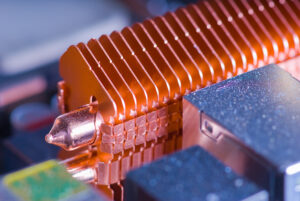

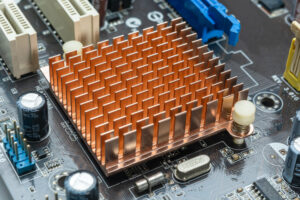

As advances in electronics and computer circuitry rapidly increase productivity, businesses must consistently upgrade their equipment. Your regular investment in your machinery helps you keep up with the competition, but it can come with additional concerns. A more powerful chipset can generate a significant amount of waste heat, and you must properly dispose of it to keep your new equipment safe. While traditional air conditioning methods could skyrocket your energy costs to keep up with your cooling needs, relying on passive heat exchange can achieve your goals without greatly affecting energy expenditures. We could help design a custom copper heat sink to conduct heat away from your electronics and prevent the risk of your equipment overheating.

At Noren Thermal Solutions, we have been helping companies like yours control their temperatures for over 55 years. This means we have the expertise necessary to evaluate your new designs and complement them with a waste heat transfer solution that keeps your machinery operating effectively and efficiently. We could consult on your current management setup or help you design one completely new. By exploring the advantages of passive heat exchange, you can adjust to the increasing demands placed upon your equipment without allowing your cooling costs to become prohibitive. (more…)

The needs of your business are constantly evolving. To stay effective, you must adapt to changing conditions on a day-to-day basis. This can often mean expanding your production equipment and utilizing the latest technological advancements. To keep your business operating efficiently, you must plan for reasons that could cause production to slow down. One of these possibilities is your expanding thermal management needs. When your appliances become more sophisticated, so too can their need to transfer waste heat elsewhere. This is why

The needs of your business are constantly evolving. To stay effective, you must adapt to changing conditions on a day-to-day basis. This can often mean expanding your production equipment and utilizing the latest technological advancements. To keep your business operating efficiently, you must plan for reasons that could cause production to slow down. One of these possibilities is your expanding thermal management needs. When your appliances become more sophisticated, so too can their need to transfer waste heat elsewhere. This is why

When you understand the laws of thermodynamics, you can make informed decisions when designing the thermal management systems at your business. Across all industries, properly managing the transfer of waste heat is critical to operating without interruption. By taking advantage of phase-change technology, you can

When you understand the laws of thermodynamics, you can make informed decisions when designing the thermal management systems at your business. Across all industries, properly managing the transfer of waste heat is critical to operating without interruption. By taking advantage of phase-change technology, you can