For the several decades that heat exchangers have been a popular thermal management solution, companies have enjoyed several important benefits in the area of electrical cooling. The more streamlined methods used to transfer electrical waste heat, compared to the cumbersome processes of chilling and circulating conditioned air, have translated to significant savings in energy usage and overhead costs. Today, the same eco-friendly heat transfer principles make modern heat exchangers, such as heat pipe assemblies, some of the most easily customizable thermal management solutions. In many applications, the right custom heat pipe assembly can significantly boost a system’s overall performance.

For the several decades that heat exchangers have been a popular thermal management solution, companies have enjoyed several important benefits in the area of electrical cooling. The more streamlined methods used to transfer electrical waste heat, compared to the cumbersome processes of chilling and circulating conditioned air, have translated to significant savings in energy usage and overhead costs. Today, the same eco-friendly heat transfer principles make modern heat exchangers, such as heat pipe assemblies, some of the most easily customizable thermal management solutions. In many applications, the right custom heat pipe assembly can significantly boost a system’s overall performance.

Transferring heat through heat pipes

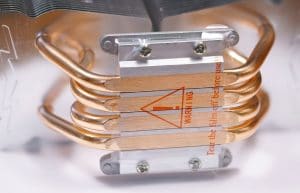

The thermal management innovation behind heat exchangers is based on natural, eco-friendly heat transfer principles that don’t rely on processes such as air conditioning or air compression. Instead, cooling units such as heat pipe assemblies utilize an eco-friendly cooling fluid that absorbs electrical waste heat at a rapid pace, then transfers and dissipates it in a cooler area of the heat exchanger (such as a custom heat sink). Within a heat pipe assembly, the fluid is able to flow back to the source of waste heat and continue absorbing and transferring heat within a self-contained loop.

The advantages of more streamlined cooling

The ability to prevent electrical systems from overheating without relying on more traditional solutions has been a significant advantage to companies in many different ways. When relying on older cooling solutions, keeping operations running smoothly can often be costly due to the energy requirements of air conditioners and air compressors. Maintaining such equipment can also be cumbersome, as the many complex moving parts can often become worn down, malfunction, or break. By contrast, heat pipe assemblies make electrical cooling a much more streamlined process, reducing the amount of energy required to keep systems cooled and the downtime required to address mechanical issues.

Customizing modern heat pipe assemblies

Heat pipes in general have proven a more efficient cooling solution than many older cooling units. Yet, as systems have advanced, heat pipes’ streamlined cooling methods have also played an important role in customizing appropriate thermal solutions for more innovative applications. For example, heat pipes can be designed to fit into tighter than usual spaces by bending and lying in any plane necessary, allowing the cooling fluid to achieve an optimal heat transfer cycle in applications that are increasingly smaller and more powerful.

For more information about improving performance with custom heat pipe assemblies, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.