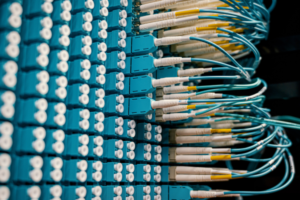

Information technology often means complexity, and if your data center or server room is lacking what it needs to stay well-maintained, it can become a real problem for you and your company. You need your equipment to have quality protection from the elements, and these concerns are not always external. Your electronics create significant heat during operation, so if you need to upgrade or replace your current thermal management, talk to a team with over 55 years of experience in the field about safeguarding server rooms and data centers.

Information technology often means complexity, and if your data center or server room is lacking what it needs to stay well-maintained, it can become a real problem for you and your company. You need your equipment to have quality protection from the elements, and these concerns are not always external. Your electronics create significant heat during operation, so if you need to upgrade or replace your current thermal management, talk to a team with over 55 years of experience in the field about safeguarding server rooms and data centers.

If you are ready to say goodbye to your current cooling concept, speak with Noren Thermal Solutions in Taylor, TX about your options in efficient cooling in information technology applications. We produce a full range of high-quality thermal management designs, such as heat exchangers, heat pipe assemblies, and superior copper heat sinks. To find out more about our commitment to your cooling needs, give us a call today and ask about the advantages of custom thermal solutions!

You need to be able to depend on your equipment, and if you cannot

You need to be able to depend on your equipment, and if you cannot  Does your business have what you need to regulate thermal energy in and around your vulnerable equipment? Are you sure? If you are still relying on traditional methods of thermal management, such as compressed air or air conditioning, then you could be throwing your money way with an unreliable or ineffective system, leaving you open to problems. Every industry is different, and each location has its own demands, so ask about

Does your business have what you need to regulate thermal energy in and around your vulnerable equipment? Are you sure? If you are still relying on traditional methods of thermal management, such as compressed air or air conditioning, then you could be throwing your money way with an unreliable or ineffective system, leaving you open to problems. Every industry is different, and each location has its own demands, so ask about  You depend on your equipment to deliver you results when you need them, and in order for them to do that efficiently, you need an

You depend on your equipment to deliver you results when you need them, and in order for them to do that efficiently, you need an  The push toward sustainability is in the minds of many businesses and entrepreneurs these days, and when done right, it can bring benefits to both the environment and your bottom line. Thankfully, within the world of thermal management, efficiency can do a lot. If you are still relying on traditional thermal management like compressed air or air conditioning for your needs, you could be wasting money on an unreliable approach. When it comes to

The push toward sustainability is in the minds of many businesses and entrepreneurs these days, and when done right, it can bring benefits to both the environment and your bottom line. Thankfully, within the world of thermal management, efficiency can do a lot. If you are still relying on traditional thermal management like compressed air or air conditioning for your needs, you could be wasting money on an unreliable approach. When it comes to  For certain fields, a little extra support is necessary to keep equipment running smoothly, and without the right protection, it could spell disaster. If you work in a challenging environment, take the time to talk to a team that understands the demands that you face each and every day. When it comes to handling your heat, that can mean learning about the

For certain fields, a little extra support is necessary to keep equipment running smoothly, and without the right protection, it could spell disaster. If you work in a challenging environment, take the time to talk to a team that understands the demands that you face each and every day. When it comes to handling your heat, that can mean learning about the  Our water is one of our most important resources, and it is one that we all share together. This means that, as a business, you need to make sure that your equipment is doing its part to keep the water supply safe. Even if you don’t think that you use water in your daily activities, your thermal management system might, and so it is vital to take a look to ensure that you are following all applicable local rules and regulations. If your

Our water is one of our most important resources, and it is one that we all share together. This means that, as a business, you need to make sure that your equipment is doing its part to keep the water supply safe. Even if you don’t think that you use water in your daily activities, your thermal management system might, and so it is vital to take a look to ensure that you are following all applicable local rules and regulations. If your

Without your equipment, your business would be lost, so you need to make sure that you are taking the time to keep things safe and optimized. When you work in a tough environment, you need to take even more precautions with how you protect your wiring, components, and machinery, and if you are continuing to rely on compressed air or air conditioning, it is time to think about making a change. With

Without your equipment, your business would be lost, so you need to make sure that you are taking the time to keep things safe and optimized. When you work in a tough environment, you need to take even more precautions with how you protect your wiring, components, and machinery, and if you are continuing to rely on compressed air or air conditioning, it is time to think about making a change. With  As a business, you need to know how to handle a lot of moving parts. In addition to the stress of managing people, you also want to make sure that you have the support you need for your equipment. Your electronics and machinery do much of the work around your office, so it only feels right to put in the work for its protection. Heat is one of the most significant dangers that a business can encounter, and

As a business, you need to know how to handle a lot of moving parts. In addition to the stress of managing people, you also want to make sure that you have the support you need for your equipment. Your electronics and machinery do much of the work around your office, so it only feels right to put in the work for its protection. Heat is one of the most significant dangers that a business can encounter, and