Many of today’s most effective technological solutions are also those that are highly customized to meet specific applications’ needs. This is especially true when it comes to electrical thermal management, as modern applications often have unique operating parameters that can be impacted differently by the efficiency of electrical cooling. To help ensure optimal customization and results from their electrical thermal management solutions, companies often rely on custom cold plate thermal solutions. With the use of customized cold plates and natural, eco-friendly thermal management processes, companies can enhance the performance and efficiencies of many of their more advanced technological solutions.

Many of today’s most effective technological solutions are also those that are highly customized to meet specific applications’ needs. This is especially true when it comes to electrical thermal management, as modern applications often have unique operating parameters that can be impacted differently by the efficiency of electrical cooling. To help ensure optimal customization and results from their electrical thermal management solutions, companies often rely on custom cold plate thermal solutions. With the use of customized cold plates and natural, eco-friendly thermal management processes, companies can enhance the performance and efficiencies of many of their more advanced technological solutions.

Advanced cooling needs of modern applications

The process of effectively preventing electrical waste heat from damaging electrical components has always been essential to the success of companies’ technologies. In more modern applications, however, the challenge of preventing electrical overheating without utilizing large amounts of space and resources is even more apparent. Companies seeking to enhance their efficiencies and productivity tend to invest in faster, more powerful, and more compact technological solutions. This means their electrical cooling solutions must be able to meet increasingly more demanding parameters, and custom thermal solutions such as liquid cold plates are often the most effective.

Custom, eco-friendly approaches to thermal management

The ability to customize thermal management in an efficient and effective manner has been one of the greatest advantages of more modern electrical cooling methods. These include the application of natural heat transfer processes, such as conduction, natural/forced convection, and phase-change cooling. Such processes are more efficient and eco-friendly than traditional methods of cooling, such as air conditioners and air compressors. They’re also easier to contain within various cooling designs, including customized cold plates that help maximize electrical cooling in a wide range of advanced applications.

The optimized performance of custom cold plates

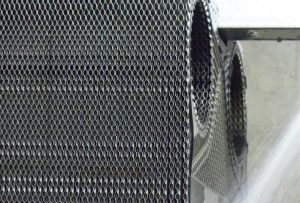

Cold plate thermal management solutions were popular even before the customization of thermal management applications was routine. The technology is based on traditional heat exchanger technologies that utilize heat transfer methods to efficiently prevent overheating. For example, within a custom-designed cold plate assembly, a cooling fluid can flow easily through the custom-machined paths through the plates. When heat is applied at any point among the plate, it can be transferred to the fluid, which then carries the waste heat away from sensitive electrical components. For more information about cooling solutions based on custom cold plates, call Noren Custom Thermal Solutions in Taylor, TX, at 866-936-6736.