Thermal management hasn’t always been a popular area of innovation for companies in most industries. Traditionally, thermal management for electrical applications relied mostly on solutions such as air conditioning and air compressing, which were designed to create and use chilled air to prevent electrical overheating. Such solutions were effective in meeting that goal, but companies typically had to shoulder the costs of high energy consumption and frequent maintenance to keep them operational. Today, however, more companies are benefiting from custom thermal solutions that optimize the thermal management process by rapidly and efficiently transferring waste heat.

Thermal management hasn’t always been a popular area of innovation for companies in most industries. Traditionally, thermal management for electrical applications relied mostly on solutions such as air conditioning and air compressing, which were designed to create and use chilled air to prevent electrical overheating. Such solutions were effective in meeting that goal, but companies typically had to shoulder the costs of high energy consumption and frequent maintenance to keep them operational. Today, however, more companies are benefiting from custom thermal solutions that optimize the thermal management process by rapidly and efficiently transferring waste heat.

Making optimal use of space

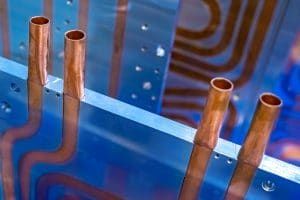

Transforming thermal management technologies by focusing on heat transfer has allowed for several different advancements in electrical cooling. Making greater use of limited space within advanced applications has proven an important benefit, especially as applications have grown smaller and sleeker as their technologies have grown more powerful. More conventional air conditioners and air compressors usually require larger spaces to accommodate the machinery they utilize. However, using natural and easily maintainable heat transfer processes, such as phase-change cooling, has allowed for custom thermal solutions that provide high-performance thermal management within smaller, minimal designs.

Using minimal amounts of energy

The ability to fit high-performance electrical cooling solutions into smaller applications is an important benefit to companies utilizing more advanced technologies. However, space isn’t the only benefit that more streamlined thermal management processes have created. For example, because they transfer heat instead of generating chilled air, custom thermal solutions don’t require as much energy to operate on a continuous basis. In fact, optimizing energy usage has proven one of the biggest advantages to using heat transfer principles to customize thermal management. The savings are often significant, especially compared to large-scale usage of air conditioners or similar thermal management solutions.

Keeping cooling processes eco-friendly

The minimal amounts of energy required to facilitate the heat transfer process is a significant factor in another important advantage that custom thermal solutions provide – the ability to keep electrical cooling processes eco-friendly. In virtually every industry, consumer demand and industry standards have forced companies to seek new and better ways to lower their impacts on the environment. Eliminating their reliance on more cumbersome solutions that require large amounts of energy and utilize potentially harmful chemicals has helped companies benefit greatly in their quest to be more eco-friendly.

For more information about the benefit of transferring heat in custom thermal solutions, call Noren Custom Thermal Solutions in Taylor, TX, at 866-936-6736.