As companies in every industry have continued to implement more advanced electrical cooling solutions, the advantages of the more streamlined processes have become much more apparent. Things like ensuring their technologies continue running efficiently and optimally have become much simpler and more affordable for many companies, thanks largely to them no longer having to rely on more cumbersome electrical cooling solutions. However, more streamlined cooling processes, such as transferring electrical waste heat, have also made several other advancements easier, particularly the customization of thermal solutions for increasingly more advanced applications.

As companies in every industry have continued to implement more advanced electrical cooling solutions, the advantages of the more streamlined processes have become much more apparent. Things like ensuring their technologies continue running efficiently and optimally have become much simpler and more affordable for many companies, thanks largely to them no longer having to rely on more cumbersome electrical cooling solutions. However, more streamlined cooling processes, such as transferring electrical waste heat, have also made several other advancements easier, particularly the customization of thermal solutions for increasingly more advanced applications.

The principles of streamlined thermal management

Introducing the process of transferring waste heat as a common industrial thermal management solution created several long-lasting impacts on most industries’ operations. It changed the way most companies viewed electrical thermal management, which, until then, was largely handled by more cumbersome solutions such as air conditioning or air compression. Unlike more conventional cooling methods, the solutions that are designed to transfer waste heat operate on more natural and eco-friendly principles of thermal management. They don’t rely on the generation and circulation of chilled air, but rather on the natural way in which certain cooling fluids absorb waste heat without allowing the temperature to rise within an enclosure.

The advantages of heat transfer technologies

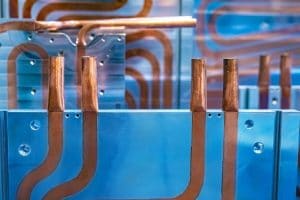

Utilizing natural heat transfer processes quickly became a preferred solution for companies, as the advantages compared to more traditional solutions are often immediately apparent. For example, transferring heat can keep most electrical enclosures properly cooled while using a minimal amount of energy, and the apparatus (such as heat pipes and cold plates) don’t consist of multiple external mechanical parts that might require frequent maintenance or repairs. The cost savings resulting from reduced energy usage and maintenance needs are beneficial enough. However, the efficiency of heat transfer techniques has also made them essential to providing sufficient cooling for more advanced technological applications.

The customization of heat transfer solutions

Saving energy and time on maintenance are important advantages to modern electrical cooling solutions, but they’ve impacted operations in most industries to even more significant degrees. For example, as companies invest in new, innovative, and sometimes proprietary technologies, their investments rely heavily on the thermal management systems that are utilized to maintain those technologies. Customizing thermal management solutions specifically for each application is easier when the solutions are designed around natural, easily maintainable heat transfer processes. For more information about why it’s easier to customize heat transfer cooling solutions, call Noren Custom Thermal Solutions in Taylor, TX, at 866-936-6736.