Getting the most out of your industrial applications is integral to your operation for a number of reasons. For instance, being able to function at your capacity not only ends up saving you in terms of cost and energy consumption but allows you to optimize your processes as well. This concept can be applied across a vast number of industries, and each one contains its own set of unique needs and parameters that need to be met. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX analyzes the plastic molding processes and shares how our custom thermal pins can streamline your thermal management capabilities in injection molds.

Getting the most out of your industrial applications is integral to your operation for a number of reasons. For instance, being able to function at your capacity not only ends up saving you in terms of cost and energy consumption but allows you to optimize your processes as well. This concept can be applied across a vast number of industries, and each one contains its own set of unique needs and parameters that need to be met. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX analyzes the plastic molding processes and shares how our custom thermal pins can streamline your thermal management capabilities in injection molds.

Versatility and Breadth of Design

Plastic molding is an industry that can be widely applied to a number of tasks. For example, manufacturing boats, bins, small plastic pieces, containers, and virtually everything in-between fall within the jurisdiction of plastic molding. What’s more? Many other industries utilize these products as well, and some may include molding capabilities in their operation.

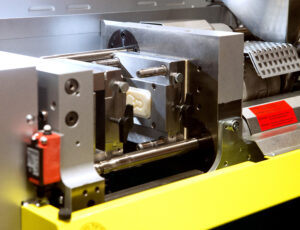

More specifically, injection molding involves injecting molten material into a specific mold. During the process, the plastic is fed into a heated barrel, mixed using a helical screw, then injected into the mold itself. Not only does this allow for the creation of a wide array of items, but it leads to efficient function as well.

The problem arises, however, when the waste heat generated by the process is not properly removed. Indeed, this can lead to uneven cooling for the product and insufficient application cooling for your equipment. To learn more about this process, reach out to a representative from our team today.

A Need for Consistency

When your operation is dependent on efficient cycle times and yielding quality products, a thermal management solution is a must. Indeed, our team can help you make the most of your plastic injection mold cooling through the use of a small isothermal heat exchanger known as a thermal pin.

Thermal pins utilize eco-friendly methods to rapidly transfer heat at high volumes, making it essential to the molding process. Further, the ability to do so methodically and consistently helps in terms of saving costs. Contact our team today to learn more about this process and how we can help.

Thermal Pin Capabilities

In addition to effective plastic injection mold cooling, thermal pins require a minimal amount of maintenance through use, so you do not have to worry about investing significant time and effort into installation and maintenance. Furthermore, these high-efficiency heat pipes enable cooling in areas previously inaccessible to options involving water cooling.

Speak with our Team

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to learn more about the function of thermal pins, and how our team can help you optimize your plastic injection mold cooling capabilities.