When everything is functioning smoothly, you can count on increased yields, reduced cycle times, and more. From time to time, however, you may endure mechanical breakdown, application overheating, and a variety of other concerns that can significantly impact or halt productivity altogether. Though this phenomenon may not occur frequently, the truth of the matter is that it may just be enough to hold up production and cost your company significantly. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX examines how this phenomenon affects the plastic mold industry, and how custom thermal solutions can help.

When everything is functioning smoothly, you can count on increased yields, reduced cycle times, and more. From time to time, however, you may endure mechanical breakdown, application overheating, and a variety of other concerns that can significantly impact or halt productivity altogether. Though this phenomenon may not occur frequently, the truth of the matter is that it may just be enough to hold up production and cost your company significantly. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX examines how this phenomenon affects the plastic mold industry, and how custom thermal solutions can help.

Understanding Material Processing

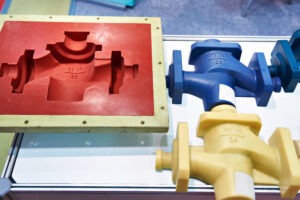

It goes without saying that many industries out there benefit significantly from those that perform material processing. Indeed, material processing involves taking raw materials and transforming them into specific products, such as using raw plastic to create bins, bottles, and virtually everything else in-between.

Material processing is a valuable market, as there are plenty of businesses that utilize these products to package their own. For example, food and beverage industries may outsource their bottles from a material processing company so that, once on the line, they can be filled, sealed, and ready to ship.

When it comes to the process of creating these products, however, it is important to note the many parameters that are involved. For example, the material must be able to be heated and subsequently cooled in a rapid manner so that cycle times remain low. On the converse, workers must be cautious as to the temperatures the products are reaching, as too extreme of a temperature can cause noticeable blemishes such as pulling, sink marks, and hot spots. To learn more about this process, reach out to our team today.

Cooling Machine Molds

When considering the cooling process, it is important to recognize the intricacies of the molds themselves. As a matter of fact, reaching all areas in the past has proven difficult, but fortunately, that is where our custom thermal pins come in to help.

A thermal pin is a small heat exchanger that allows cooling in areas previously inaccessible to mold cooling tactics. Further, it allows for effective plastic injection mold cooling, plastic rotational mold cooling, and even blow and extrusion molding. For more information about this process, give our team a call today.

Multiple Options to Suit Your Needs

The best part about our thermal pin heat exchangers is that they can be custom-tailored to fit your needs. Indeed, whether you are working with blow molding, extrusion, rotational, or even injection molding, our team can customize your thermal solutions to meet your exact needs.

Speak with Our Team

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to learn more about the benefits of custom thermal pins to satisfy your plastic molding needs.