In our previous blog post, we discussed the manufacturing process with our team, and how it ensures oversight from start to finish. While many people may opt to outsource certain stages of the process, we believe that quality solutions are the result of consistent and dependable care throughout every stage. This includes design conceptualization all the way to manufacturing and selling products. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX highlights the role of rapid prototyping within this process and how it promotes cost and energy efficiency.

In our previous blog post, we discussed the manufacturing process with our team, and how it ensures oversight from start to finish. While many people may opt to outsource certain stages of the process, we believe that quality solutions are the result of consistent and dependable care throughout every stage. This includes design conceptualization all the way to manufacturing and selling products. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX highlights the role of rapid prototyping within this process and how it promotes cost and energy efficiency.

Understanding Our Role in the Process

Accomplishing your thermal projects, regardless of how large or small, can be made easier with the help of a thermal management expert. Indeed, our goal for over fifty years has been to offer the most in terms of application cooling and function, and we believe you do not have to make the sacrifices that other manufacturers are telling you. After all, there is a common misconception that to get the most from an application, you must utilize solutions that are not necessarily ideal for the environment or cost a significant amount. We are here to tell you that this simply is not the case.

You see, the notion that optimal function is a product of fossil fuel usage or of great financial expense is just as outdated as the one-size-fits-all model. There is no way to get the most from your setup without considering your unique parameters, and rapid prototyping is one of the many steps we implement to help. Our team takes the time to truly get to know your needs and test ideas earlier in the process so we can ensure both cost and energy efficiency. To learn more about this process, give our team a call today.

Identifying Strengths and Weaknesses

In order to help you get the most from your devices, our team tries to test concepts earlier in the process. Not only does this allow for cost savings, but it can help uncover strengths and weaknesses of the design earlier in the process.

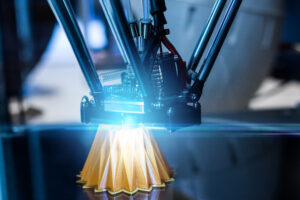

The last thing you want to experience is a major complication or hiccup after your device has been manufactured. With the help of 3D printing technology, we can prototype a design within 24-48 hours. Contact our team to learn more today.

Working Out Potential Issues Early

The sooner we are able to identify potential issues in a solution, the better the outcome will be. As we mentioned previously, it provides cost savings and energy efficiency, so you can rest assured knowing that your product will provide the optimal solution for your specific parameters and needs.

Speak with Our Team

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative from our team to learn more about the many benefits of rapid prototyping, and get started today.