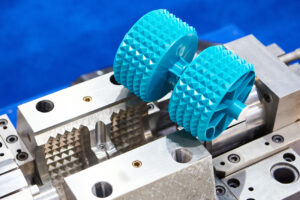

While 3D printing has been attracting the attention of many headlines over the past decade, injection molding is still the most widely used plastic components manufacturing process. Injection molding is used for nearly any consumer product you can think of, and its variety of applications enjoy efficient costs when producing a large number of parts per hour. With the opportunity to create a large amount of product, this manufacturing process creates a large amount of heat. This means relying upon a high-quality thermal management system to keep your operation running smoothly. Without proper heat transfer, you risk creating a product that does not meet your standards or increasing costs by inefficiently applying energy when you need to stay in a desired temperature range.

When it comes to redirecting heat from your industrial or technological applications, you can rely on the expert team at Noren Thermal Solutions in Taylor, TX. For more than 50 years, we have developed relationships with clients who have a varied set of plastic production needs, and we can offer you the same help to manage the transfer of heat with your processes. With a custom thermal pin system from Noren, you can increase cycle times and produce molds with consistently higher quality.

Increase The Quality Of Your Plastic Products

Producing a high-quality plastic product consistently requires careful control over the heat transfer process. By keeping temperatures in a specific range, you allow your plastic to properly spread throughout the entire mold and cool on design. When this process is performed correctly, you can enjoy a product that you are proud to offer to your customers. If your thermal pins are out of date or no longer manage heat consistently, you might be creating a subpar product and suffering higher costs.

Advanced Thermal Pins Are Customized For Your Molding Process

Our thermal pins and recharge cores are custom designed to improve the efficiency of your injection molding process. A thermal pin is a special heat pipe integrated into your coolant design system to allow for optimal transfer of energy. Our custom design moves energy more evenly from your mold to help you save on costs.

Call Noren In Taylor, TX To Discuss Your Injection Molding Production Needs

Call Noren Thermal Solutions in Taylor, TX at 512-595-5700 to speak with a representative and discuss your production needs. If you have a plastic production process that would benefit from more efficient cooling, we have solutions that decrease your costs while increasing the quality of your product. Work with our team to identify areas of your operation where we can provide help. You can prevent delays in production with a custom solution from Noren and deliver a product you are proud of!