Creating methods and processes that improve productivity and efficiency has always been an important strategy in most companies’ quests to become more competitive. Many of those methods and techniques involve the implementation of more advanced and powerful technologies, which can help significantly boost production and business management when implemented properly. However, with this implementation has also come the need to improve the management of these technologies, particularly the thermal management processes that are designed to keep the systems running effectively and efficiently. By utilizing more advanced, eco-friendly, and customized thermal management solutions, companies have been able to fill that need and make enhancing their productivity much simpler. (more…)

Creating methods and processes that improve productivity and efficiency has always been an important strategy in most companies’ quests to become more competitive. Many of those methods and techniques involve the implementation of more advanced and powerful technologies, which can help significantly boost production and business management when implemented properly. However, with this implementation has also come the need to improve the management of these technologies, particularly the thermal management processes that are designed to keep the systems running effectively and efficiently. By utilizing more advanced, eco-friendly, and customized thermal management solutions, companies have been able to fill that need and make enhancing their productivity much simpler. (more…)

Our Blog

How to Customize Thermal Solutions for More Rugged Uses

The role of electrical thermal management can have a few key differences in different industries. This is due to the nature of how these industries utilize advanced technologies, and what their solutions require in terms of efficient and reliable electrical cooling. However, in applications where technology is utilized outdoors and in rough conditions rather than in a warehouse or production facility, performance has to do with much more than just efficiency. When customizing thermal solutions for more rugged applications, there are several other important factors that must be taken into consideration. (more…)

The role of electrical thermal management can have a few key differences in different industries. This is due to the nature of how these industries utilize advanced technologies, and what their solutions require in terms of efficient and reliable electrical cooling. However, in applications where technology is utilized outdoors and in rough conditions rather than in a warehouse or production facility, performance has to do with much more than just efficiency. When customizing thermal solutions for more rugged applications, there are several other important factors that must be taken into consideration. (more…)

How to Enhance Plastic Mold Cooling with Thermal Pins

While thermal management may have some significance in every industry, companies in the plastic molding industry rely on it for more than just effectively cooling electrical enclosures. Plastic molding companies rely on high-performance heat transfer solutions to rapidly remove heat from fresh molds, a process that’s been perfected by various heat exchanger and other advanced thermal management solutions. Within the realm of plastic mold cooling, specialized cooling solutions known as custom thermal pins have proven invaluable as a way to achieve the rapid, nearly isothermal heat removal that modern companies depend on. (more…)

While thermal management may have some significance in every industry, companies in the plastic molding industry rely on it for more than just effectively cooling electrical enclosures. Plastic molding companies rely on high-performance heat transfer solutions to rapidly remove heat from fresh molds, a process that’s been perfected by various heat exchanger and other advanced thermal management solutions. Within the realm of plastic mold cooling, specialized cooling solutions known as custom thermal pins have proven invaluable as a way to achieve the rapid, nearly isothermal heat removal that modern companies depend on. (more…)

Advanced Ways to Transfer Heat in Custom Thermal Solutions

With the many different advantages to advanced, custom thermal solutions, it can often be surprising to realize these advantages stem from simpler and more natural processes. For instance, traditional electrical cooling methods used to involve the use of chilled air to keep electrical enclosures cooled. However, instead of making it more efficient to use chilled air, many modern thermal management solutions approach electrical cooling by creating ways to efficiently transfer waste heat. This has led to significant boosts in efficiency and productivity for companies in every industry, and has also paved the way for widespread adoption of more advanced, custom-designed thermal management solutions. (more…)

With the many different advantages to advanced, custom thermal solutions, it can often be surprising to realize these advantages stem from simpler and more natural processes. For instance, traditional electrical cooling methods used to involve the use of chilled air to keep electrical enclosures cooled. However, instead of making it more efficient to use chilled air, many modern thermal management solutions approach electrical cooling by creating ways to efficiently transfer waste heat. This has led to significant boosts in efficiency and productivity for companies in every industry, and has also paved the way for widespread adoption of more advanced, custom-designed thermal management solutions. (more…)

Important Elements of Custom Thermal Management

The ability to customize various types of technology has been an important aspect of how many companies have improved their overall operations. This is especially true when it comes to the realm of electrical thermal management, where many factors have traditionally made customization difficult and costly. Today, however, simpler heat transfer methods and more streamlined cooling designs have made customizing thermal management a much more effective and efficient process. Combining elements of advanced technology and simpler, more natural methods of transferring waste heat, custom thermal solutions have become one of the most beneficial advancements for companies in nearly every industry. (more…)

The ability to customize various types of technology has been an important aspect of how many companies have improved their overall operations. This is especially true when it comes to the realm of electrical thermal management, where many factors have traditionally made customization difficult and costly. Today, however, simpler heat transfer methods and more streamlined cooling designs have made customizing thermal management a much more effective and efficient process. Combining elements of advanced technology and simpler, more natural methods of transferring waste heat, custom thermal solutions have become one of the most beneficial advancements for companies in nearly every industry. (more…)

How Companies Save Costs with Custom Thermal Solutions

When companies in most industries invest in new technologies and business processes, the aim is typically to boost productivity and efficiency while tightly managing or reducing overall operating costs. While thermal management solutions don’t always get as much attention as other areas of investment, advancements in the field have proven essential to many companies’ efforts at streamlining their operations. With more efficient, effective, and eco-friendly custom thermal solutions, companies can save significantly on several different overhead costs, including the overall consumption of energy and productivity lost due to frequent repairs and maintenance. (more…)

When companies in most industries invest in new technologies and business processes, the aim is typically to boost productivity and efficiency while tightly managing or reducing overall operating costs. While thermal management solutions don’t always get as much attention as other areas of investment, advancements in the field have proven essential to many companies’ efforts at streamlining their operations. With more efficient, effective, and eco-friendly custom thermal solutions, companies can save significantly on several different overhead costs, including the overall consumption of energy and productivity lost due to frequent repairs and maintenance. (more…)

The Benefit of Transferring Heat in Custom Thermal Solutions

Thermal management hasn’t always been a popular area of innovation for companies in most industries. Traditionally, thermal management for electrical applications relied mostly on solutions such as air conditioning and air compressing, which were designed to create and use chilled air to prevent electrical overheating. Such solutions were effective in meeting that goal, but companies typically had to shoulder the costs of high energy consumption and frequent maintenance to keep them operational. Today, however, more companies are benefiting from custom thermal solutions that optimize the thermal management process by rapidly and efficiently transferring waste heat. (more…)

Thermal management hasn’t always been a popular area of innovation for companies in most industries. Traditionally, thermal management for electrical applications relied mostly on solutions such as air conditioning and air compressing, which were designed to create and use chilled air to prevent electrical overheating. Such solutions were effective in meeting that goal, but companies typically had to shoulder the costs of high energy consumption and frequent maintenance to keep them operational. Today, however, more companies are benefiting from custom thermal solutions that optimize the thermal management process by rapidly and efficiently transferring waste heat. (more…)

Phase-Change Cooling Solutions for Advanced Applications

As thermal management technologies and techniques have evolved over the decades, more companies have taken advantage of high-performance passive cooling solutions for some of the more advanced applications. In many instances, the use of methods such as phase-change cooling has proven one of the most advantageous types of custom thermal solutions. By enhancing companies’ electrical cooling capacities and making heat transfer more efficient, custom phase-change cooling solutions have helped companies in virtually every industry streamline a wide range of thermal management processes. (more…)

As thermal management technologies and techniques have evolved over the decades, more companies have taken advantage of high-performance passive cooling solutions for some of the more advanced applications. In many instances, the use of methods such as phase-change cooling has proven one of the most advantageous types of custom thermal solutions. By enhancing companies’ electrical cooling capacities and making heat transfer more efficient, custom phase-change cooling solutions have helped companies in virtually every industry streamline a wide range of thermal management processes. (more…)

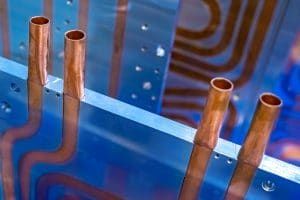

Cooling Solutions Based on Custom Cold Plates

Many of today’s most effective technological solutions are also those that are highly customized to meet specific applications’ needs. This is especially true when it comes to electrical thermal management, as modern applications often have unique operating parameters that can be impacted differently by the efficiency of electrical cooling. To help ensure optimal customization and results from their electrical thermal management solutions, companies often rely on custom cold plate thermal solutions. With the use of customized cold plates and natural, eco-friendly thermal management processes, companies can enhance the performance and efficiencies of many of their more advanced technological solutions. (more…)

Many of today’s most effective technological solutions are also those that are highly customized to meet specific applications’ needs. This is especially true when it comes to electrical thermal management, as modern applications often have unique operating parameters that can be impacted differently by the efficiency of electrical cooling. To help ensure optimal customization and results from their electrical thermal management solutions, companies often rely on custom cold plate thermal solutions. With the use of customized cold plates and natural, eco-friendly thermal management processes, companies can enhance the performance and efficiencies of many of their more advanced technological solutions. (more…)

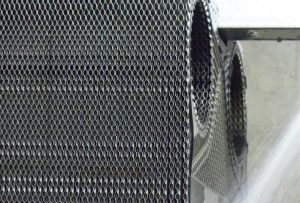

A Look at the Value of Custom Heat Pipe Solutions

The total value of any advanced electrical thermal management solution goes beyond the specific cooling operations that it’s responsible for. For example, the more efficiently a solution handles the thermal management needs of an application, the lower the impact it will have on the company’s overhead costs, downtime, employee productivity, and more. Because of this, companies have continued to focus on implementing thermal solutions that offer the utmost efficiency and productivity. In many cases, the most efficient solutions are those that are designed specifically for certain applications’ needs, such as advanced custom heat pipe assemblies. (more…)

The total value of any advanced electrical thermal management solution goes beyond the specific cooling operations that it’s responsible for. For example, the more efficiently a solution handles the thermal management needs of an application, the lower the impact it will have on the company’s overhead costs, downtime, employee productivity, and more. Because of this, companies have continued to focus on implementing thermal solutions that offer the utmost efficiency and productivity. In many cases, the most efficient solutions are those that are designed specifically for certain applications’ needs, such as advanced custom heat pipe assemblies. (more…)