For a number of industries, finding the most effective methods of cooling during manufacturing and molding processes is a challenge. Fortunately, Noren Thermal Solutions in Taylor, TX has risen to the challenge! Our company provides thermal management solutions that are innovative, eco-friendly, and provide higher yields for our clients. In today’s blog, we’re going to take a look at a few of our advanced thermal solutions.

Phase-Change Cooling

With phase-change cooling, a heat exchanger can quickly move large amounts of water heat using only the cooling fluid’s latent heat of vaporization. Also known as two-phase cooling, this involves the fluid being exposed to a heat source and absorbing the heat until it vaporizes. While evaporating, the heated and now less dense fluid is easily moved into the heat sink, releasing the heat back into a fluid. The process is environmentally friendly, and creates a continuous loop without a major rise in temperature!

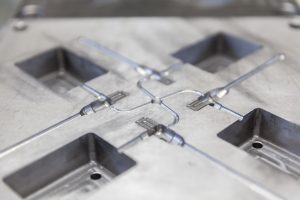

Plastic Mold Cooling

Advances in cooling technology offer those in the molding industry access to increased cycle times, high quality molds, and greater yields. Using thermal pins, we can cool previously inaccessible areas for injection molding and draw heat and transfer it to remote water channels. For rotational and rubber molding, we can transfer heat quickly and evenly, regardless of the thickness of the mold itself. For blow molding, we uniformly cool the end of each blow pin, and evenly cool the necks of bottles. For extrusion molding, we eliminate heat spots, preventing sink marks, pulling, and spotting.

Passive and Active Cooling

Our solutions could include two different convective heat transfers. Passive involves the fluid being displaced when coming into contact with heat, transferring heat to the dense, cooler fluid without an external source. Active cooling will force the fluid over a surface with the use of an external source, creating an artificial convection current.

Thermoelectric

With our thermoelectric coolers, we create temperature differences using two electric conjunctions to transfer heat. A voltage applied to the joined conductors creates an electric current, which flows through the junction of these two conductors. Heat is removed from one and cools it, and the heat is then deposited at the other, creating the Peltier Effect.

If you have any questions about our advanced solutions for thermal cooling, or if you would like to discuss implementing these heat exchanging technologies at your facility, then please feel free to contact our team for more information.

Do You Have Any Questions?

For more information about the heat exchanging and cooling technologies we provide, contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a member of our team today. We look for to helping you incorporate cost-saving, efficient, and eco-friendly cooling systems at your company.