In order to stay ahead of the curve and continue to thrive in a competitive market, a number of factors and considerations must be met. Above all else, the ability to protect your devices from overheating, breakdown, and more is a top priority. Still, however, that does not mean that efficient, environmentally-friendly approaches should be thrown out of the window. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the role efficiency plays in application performance, and how your equipment could benefit from customized heat sink enclosure cooling.

In order to stay ahead of the curve and continue to thrive in a competitive market, a number of factors and considerations must be met. Above all else, the ability to protect your devices from overheating, breakdown, and more is a top priority. Still, however, that does not mean that efficient, environmentally-friendly approaches should be thrown out of the window. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the role efficiency plays in application performance, and how your equipment could benefit from customized heat sink enclosure cooling.

Understanding Thermal Dissipation

In order to help you get the most out of your technological applications, you must first gain an understanding of your thermal budget and capabilities. Indeed, not all machines require the same level of attention, nor can the same one-size-fits-all approach optimize their output, and this is why a better understanding of your technological needs and parameters yields more effective and efficient results.

When examining your different heat exchanger options, you should consider what concept or method might work best for your environment. For instance, we take a look at the primary methods of heat spreading, movement, and dissipation.

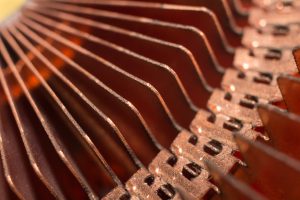

With respect to dissipation, one of our more popular solutions involves heat sink enclosure cooling. A heat sink is a thermal management solution that consists of a solid base and multiple fins that jut out from the base, allowing waste heat to more easily spread and dissipate into the surrounding air. To learn more about this process and speak with a member of our team, contact us today.

How Materials Make a Difference

For custom heat sink enclosure cooling to be effective, you must recognize the important role that composition material plays. For instance, most heat sinks utilize aluminum to achieve effective thermal management but bear in mind, there are other options that have been proven more effective.

Indeed, our team opts for using copper as opposed to aluminum, as it contains a rate of thermal transfer that is nearly two to three times higher than that of traditional aluminum models. This allows your industrial applications to cool at a much more rapid rate, and thus affording shorter cycle times, higher yields, and the ability to optimize your process.

Optimizing Function Naturally

Another major benefit that arises from heat sink enclosure cooling is that it does not harm the environment – both physically and working. Indeed, thermal management can be accomplished in a variety of ways, but there are not that many that can optimize function without significantly impacting the environment. Fortunately, our eco-friendly solutions can.

Learn More Today

To learn more about the benefits of heat dissipation and optimized function, contact the team at Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 and speak to a representative today.