It goes without saying that there are several different ways to get to a single conclusion or result. This notion is true for a variety of circumstances, including finding solutions for optimal thermal management. Indeed, application cooling can occur as a result of passive or active convective heat transfer, thermoelectric means, and even through the use of phase-change technology. Still, not every method is ideal for your needs, and our team is ready to help you determine the best course of action to achieve your goals. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a more detailed look at the way phase-change technology works and how it is used in various applications.

It goes without saying that there are several different ways to get to a single conclusion or result. This notion is true for a variety of circumstances, including finding solutions for optimal thermal management. Indeed, application cooling can occur as a result of passive or active convective heat transfer, thermoelectric means, and even through the use of phase-change technology. Still, not every method is ideal for your needs, and our team is ready to help you determine the best course of action to achieve your goals. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a more detailed look at the way phase-change technology works and how it is used in various applications.

An Eco-Friendly Thermal Method

Whether you are aware of it or not, your carbon footprint has a bigger impact on the world than you might have initially expected. Indeed, pollution and damage has occurred to our planet at an unprecedented rate, and without the strong commitment to going green in many areas, our Earth will not survive.

For over fifty years, the team at Noren Products has made it our mission to not only provide thermal management solutions that optimize your capabilities, but ones that also emphasize the use of eco-friendly methods. You see, all of our products are created with these two goals in mind, and we are here to tell you that you do not have to sacrifice quality for environmental sustainability, or vice versa.

One such way that our team implements eco-friendly practices is through the use of eco-friendly methods. These include passive and active cooling using a working fluid, thermoelectric methods, and of course, phase-change technology. To learn more about this process, give our team a call today.

Using a Fluid’s Latent Point of Vaporization

Taking a closer look at phase-change technology, in particular, the primary thing to note is the use of a fluid’s latent point of vaporization. In an application, the heat source is exposed to the working fluid, oftentimes water. This allows the water to absorb the waste heat and rise in temperature until reaching its latent point of vaporization.

Once it has reached its gaseous state, the fluid is transferred over a specified distance, where it is subsequently cooled. From here, it returns back to its liquid state and is taken back to the heat source to repeat the process. Contact our team to learn more today.

Transfer to Your Heat Dissipation Structure

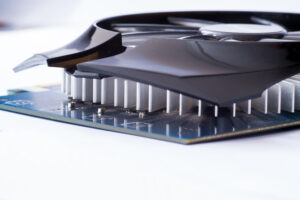

In conjunction with phase-change technology, a heat dissipation structure such as a heat sink is used to help remove the waste heat. This helps regulate internal temperatures and prevents your application from overheating.

Learn More Today

To learn more about the benefits of phase-change technology, contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 and speak to a representative from our team to get started today.