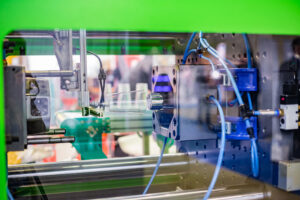

If you work in the plastics manufacturing industry, you understand that injection molding is still king for many companies. While advancements in other technologies like 3D printing are being developed, injection molding provides a tried and true method for producing plastics at a large scale. Across a wide variety of industries, this desired manufacturing process employs heat transfer to create a smooth even distribution throughout the entire mold. Because temperature management is key to the quality of the finished product, receiving a thermal pin system from thermal management experts can put you on the path to success. Cheaper materials could result in an inefficient design process as you fail to reproduce your desired end product.

At Noren Thermal Solutions, we have been in business for more than five decades helping companies like yours manage heat throughout all sorts of industrial processes. This means we have decades of experience helping plastic producers fine-tune their systems to both save costs and greatly increase quality. Our engineering team constantly reviews the quality of our thermal pins to ensure they meet your high standards for production. When you work with Noren, you can increase cycle times with consistently higher-quality molds.

Creating Plastic Products That Meet Your Demands

When designing a new plastic product, you understand the connection between its quality and the control you can maintain over the distribution of heat transfer. When you are better equipped to keep your temperatures in a certain range, you can avoid an uneven spread of plastic through the mold. We can take a look at your current pin system to let you know if it is up to date. Otherwise, we could help plan and install a new set that helps you achieve your production goals.

Building A Custom Thermal Pin Set For Your Application

We could design a custom set of thermal pins and recharge cores to help you increase the efficiency of your injection molding applications. Think of a thermal pin as a high-temperature heat pipe that transfers heat extremely quickly through your molding equipment. When is absorbed at an accelerated rate, your yields go up by taking less cycle time. By custom designing a pin for your mold itself, you can get better results than with a more generic product.

Talk To Noren Thermal Solutions To Discuss Your Injection Molding Production Process

To find out more about how we can help you transfer heat in plastics production, call a team member at Noren Thermal Solutions at (512) 595-5700 to talk about your specific applications. We are standing by to help identify areas where we can help you reduce costs and increase efficiency. This could include customizing a set of thermal pins to meet your production process.