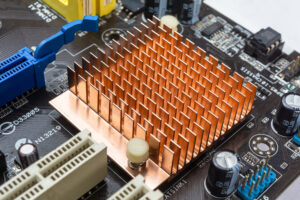

When it comes to thermal exchange, there are two distinct methods of moving heat. Both of these are helpful in protecting your equipment, but one may be more suitable for your needs than the other. So what, exactly, is the difference, and how do you make the decision between each of them?

When it comes to thermal exchange, there are two distinct methods of moving heat. Both of these are helpful in protecting your equipment, but one may be more suitable for your needs than the other. So what, exactly, is the difference, and how do you make the decision between each of them?

At Noren Thermal Solutions in Taylor, TX, we are here to help you make the right choices in your thermal management. Since 1968, we have been working alongside business owners and operators to ensure that your thermal management needs are met, and that starts with a dedication to the craft. Both passive and active solutions can be helpful in giving you an ecologically friendly way of handling your heat, but each has its own strengths. Learn a little bit about how these methods operate, and then give us a call to learn more about your choices! (more…)

Taking care of your company’s investments is a key part of owning or operating your business, and sometimes, it can also be the right thing to do. If you have

Taking care of your company’s investments is a key part of owning or operating your business, and sometimes, it can also be the right thing to do. If you have  Does your company rely upon a local server system to run your day-to-day operations? In the twenty-first century, it is nearly impossible to find a business that doesn’t! As computers become more and more powerful, they can produce significant excess heat waste that threatens their ability to operate efficiently. Without safely transferring the

Does your company rely upon a local server system to run your day-to-day operations? In the twenty-first century, it is nearly impossible to find a business that doesn’t! As computers become more and more powerful, they can produce significant excess heat waste that threatens their ability to operate efficiently. Without safely transferring the  When you make operational decisions at your company, protecting your equipment from hazardous conditions is a primary concern. You understand how important your infrastructure is to day-to-day operations, and

When you make operational decisions at your company, protecting your equipment from hazardous conditions is a primary concern. You understand how important your infrastructure is to day-to-day operations, and  If you are in charge of equipment selection at your company, you understand that pursuing efficiency while maintaining a high safety standard can be a balancing act. Without cutting corners, you want to reduce costs while at the same time ensuring that your employees can count on your protection. If you install a piece of machinery that produces a

If you are in charge of equipment selection at your company, you understand that pursuing efficiency while maintaining a high safety standard can be a balancing act. Without cutting corners, you want to reduce costs while at the same time ensuring that your employees can count on your protection. If you install a piece of machinery that produces a  Part of managing your business means anticipating situations that can disrupt your operation. When it comes to applications that generate a significant amount of heat waste, the right approach to thermal management can make all the difference between success and failure. That’s because overheating can lead to seriously

Part of managing your business means anticipating situations that can disrupt your operation. When it comes to applications that generate a significant amount of heat waste, the right approach to thermal management can make all the difference between success and failure. That’s because overheating can lead to seriously

If you are in charge of operations at your company, you know how important

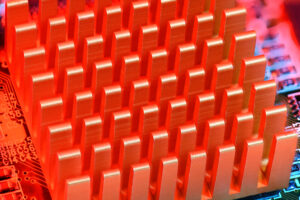

If you are in charge of operations at your company, you know how important  When you are in charge of making planning decisions at your company, you understand that protecting your equipment begins before purchases are even made. If designing a new application that generates significant heat waste, you may perform analyses of the costs required to cool such machinery. By exploring your options for passive forms of thermal management, you can take advantage of phase-change technology to reduce your energy requirements. With systems such as custom heat pipes, you can keep your temperatures in the appropriate range without the use of outside electricity.

When you are in charge of making planning decisions at your company, you understand that protecting your equipment begins before purchases are even made. If designing a new application that generates significant heat waste, you may perform analyses of the costs required to cool such machinery. By exploring your options for passive forms of thermal management, you can take advantage of phase-change technology to reduce your energy requirements. With systems such as custom heat pipes, you can keep your temperatures in the appropriate range without the use of outside electricity.  If you own or operate your own business, you put a priority on safe and efficient operation in all aspects of your company. If your applications produce large amounts of heat waste,

If you own or operate your own business, you put a priority on safe and efficient operation in all aspects of your company. If your applications produce large amounts of heat waste,