Ensuring your industrial applications are functioning properly is necessary for a variety of reasons. For instance, being able to keep up with and exceed the competition is a must for a number of industries. Another important aspect is that time is money, and having to expend a great amount of time and energy into maintenance, repairs, or replacement will inevitably lead to more concerns down the line. Because of this, the last thing you want to have to deal with is inconsistent quality as your accessories are constructed. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the benefits of in-house manufacturing, and how it contributes to a quality thermal management solution.

Ensuring your industrial applications are functioning properly is necessary for a variety of reasons. For instance, being able to keep up with and exceed the competition is a must for a number of industries. Another important aspect is that time is money, and having to expend a great amount of time and energy into maintenance, repairs, or replacement will inevitably lead to more concerns down the line. Because of this, the last thing you want to have to deal with is inconsistent quality as your accessories are constructed. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the benefits of in-house manufacturing, and how it contributes to a quality thermal management solution.

Our Blog

Moving Past One-Size-Fits-All Approaches

As technology continues to evolve and advance, many industries are adopting new methods of production that not only increase productivity but keep them in the running with competitors as well. Indeed, the dependency on reliable equipment has only gone up over the years with no sign of declining any time soon. Because of this, however, an emphasis on customization has begun to take the industry by storm. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX detail the importance of customization when it comes to thermal management, and how our team can help.

As technology continues to evolve and advance, many industries are adopting new methods of production that not only increase productivity but keep them in the running with competitors as well. Indeed, the dependency on reliable equipment has only gone up over the years with no sign of declining any time soon. Because of this, however, an emphasis on customization has begun to take the industry by storm. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX detail the importance of customization when it comes to thermal management, and how our team can help.

Technologies That Achieve A Variety of Dimensions

Because each and every industry contains unique parameters and needs, it would be ineffective to assume one-size-fits-all solutions would suffice. What’s more? Not every industrial application utilizes the same equipment, let alone the same methods for effective thermal management. Still, despite all of this variation, one thing remains constant: your applications require proper maintenance and care. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways that heat exchangers such as heat pipes can achieve a variety of bends and angles to help you maximize your thermal management capabilities.

Because each and every industry contains unique parameters and needs, it would be ineffective to assume one-size-fits-all solutions would suffice. What’s more? Not every industrial application utilizes the same equipment, let alone the same methods for effective thermal management. Still, despite all of this variation, one thing remains constant: your applications require proper maintenance and care. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways that heat exchangers such as heat pipes can achieve a variety of bends and angles to help you maximize your thermal management capabilities.

Dependability In Hazardous Locations

In an ideal world, your company could achieve optimal thermal management without the need for a heat exchanger that costs you an arm and a leg. Indeed, a one-size-fits-all solution may be able to prevent overheating, but understanding that cycle times, quality products, and the like are what places a successful competitive company one step above the rest. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains what factors contribute to your thermal management needs, and how a custom heat exchanger can provide consistency in hazardous locations.

In an ideal world, your company could achieve optimal thermal management without the need for a heat exchanger that costs you an arm and a leg. Indeed, a one-size-fits-all solution may be able to prevent overheating, but understanding that cycle times, quality products, and the like are what places a successful competitive company one step above the rest. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains what factors contribute to your thermal management needs, and how a custom heat exchanger can provide consistency in hazardous locations.

Thermoelectric Methods Regulate Temperatures

It goes without saying that there are a variety of methods to ensure proper thermal management within an overheating application, and each one could be better suited for specific industries, tasks, and more. Indeed, the basis of our products stems from eco-friendly technologies and methods, such as heat spreading, movement, and dissipation. This is to ensure higher efficiency as well as eco-consciousness, and we are ready to work with you to create your ideal product. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at thermoelectric methods in particular, and how they can optimize your application function in a relatively simple manner.

It goes without saying that there are a variety of methods to ensure proper thermal management within an overheating application, and each one could be better suited for specific industries, tasks, and more. Indeed, the basis of our products stems from eco-friendly technologies and methods, such as heat spreading, movement, and dissipation. This is to ensure higher efficiency as well as eco-consciousness, and we are ready to work with you to create your ideal product. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at thermoelectric methods in particular, and how they can optimize your application function in a relatively simple manner.

The Science Behind Cold Plate Cooling

When it comes to helping you get the most out of your technological applications, there are a number of considerations to keep in mind. First, the purpose of your equipment plays a major role in its function and therefore its maintenance, meaning you must understand the ins and outs of your machines in order to best service them and keep them running smoothly. Your environment also plays a major role in what technologies will be most efficient to prevent overheating, and so on and so forth. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will examine the way cold plate heat exchangers can regulate internal application temperatures, even in cramped spaces.

When it comes to helping you get the most out of your technological applications, there are a number of considerations to keep in mind. First, the purpose of your equipment plays a major role in its function and therefore its maintenance, meaning you must understand the ins and outs of your machines in order to best service them and keep them running smoothly. Your environment also plays a major role in what technologies will be most efficient to prevent overheating, and so on and so forth. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will examine the way cold plate heat exchangers can regulate internal application temperatures, even in cramped spaces.

What To Know About Air To Water Cooling

In our previous blog, we took a look at the differences between natural and forced convection cooling, which consists of transfer heat between two different mediums such as from a solid to a fluid. Indeed, fluids such as water have proven an excellent method for industrial application cooling, as it leads to a significant number of benefits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the concept of convection a bit further and sheds some light on the way water plays a massive role in effective air to water cooling within technological applications.

In our previous blog, we took a look at the differences between natural and forced convection cooling, which consists of transfer heat between two different mediums such as from a solid to a fluid. Indeed, fluids such as water have proven an excellent method for industrial application cooling, as it leads to a significant number of benefits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the concept of convection a bit further and sheds some light on the way water plays a massive role in effective air to water cooling within technological applications.

Understanding Natural And Forced Cooling

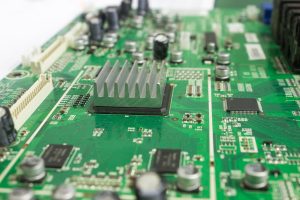

Thermal management solutions such as heat sinks, cold plates, and more all aim to achieve the same task: preventing your sensitive electronics from overheating. Indeed, regardless of the intricacies and parameters your equipment contains, overheating is always going to be a concern that must be addressed. What’s more? Taking the time to garner a thorough understanding of the unique needs that accompany your devices will aid you greatly in not only managing application cooling but helping you get the most from your devices as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at two means of accomplishing this task known as natural and forced convection, and how either process can help you.

Thermal management solutions such as heat sinks, cold plates, and more all aim to achieve the same task: preventing your sensitive electronics from overheating. Indeed, regardless of the intricacies and parameters your equipment contains, overheating is always going to be a concern that must be addressed. What’s more? Taking the time to garner a thorough understanding of the unique needs that accompany your devices will aid you greatly in not only managing application cooling but helping you get the most from your devices as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at two means of accomplishing this task known as natural and forced convection, and how either process can help you.

What To Expect From Your Heat Sink

Ensuring your industrial applications are functioning as they should means having an understanding of the technologies that help them run. Indeed, custom heat exchangers assist by preventing your machines from overheating, but is that enough in an age driven by demand and competition? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the science behind one of our primary heat exchanger models – the heat sink – and explain how eco-friendly methods help ensure optimal function.

Ensuring your industrial applications are functioning as they should means having an understanding of the technologies that help them run. Indeed, custom heat exchangers assist by preventing your machines from overheating, but is that enough in an age driven by demand and competition? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the science behind one of our primary heat exchanger models – the heat sink – and explain how eco-friendly methods help ensure optimal function.

Application Benefits From Custom Heat Exchangers

By now you are probably fully aware of the importance of effective application function. After all, your company relies heavily on these devices to accomplish a myriad of tasks around the clock, and the number one way to ensure this occurs is to provide internal application cooling. Still, not every device is created with this in mind, and additional accessories may need to be sought in order to help you get the most out of the process. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance of heat exchangers in machine function, and how customization can help you get the most from your applications.

By now you are probably fully aware of the importance of effective application function. After all, your company relies heavily on these devices to accomplish a myriad of tasks around the clock, and the number one way to ensure this occurs is to provide internal application cooling. Still, not every device is created with this in mind, and additional accessories may need to be sought in order to help you get the most out of the process. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance of heat exchangers in machine function, and how customization can help you get the most from your applications.