In order to get the most from your technological applications, you must first gain an understanding of how your unique environment and parameters influence your capabilities. Indeed, many applications tout the ability to optimize your overall results, but this cannot be done when these needs are not considered, as each person’s environment, space allotted for equipment, and more can contribute to sub-par performance. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how this concept is even more true for applications in hazardous locations, as well as how our line of HazLoc solutions can help.

In order to get the most from your technological applications, you must first gain an understanding of how your unique environment and parameters influence your capabilities. Indeed, many applications tout the ability to optimize your overall results, but this cannot be done when these needs are not considered, as each person’s environment, space allotted for equipment, and more can contribute to sub-par performance. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how this concept is even more true for applications in hazardous locations, as well as how our line of HazLoc solutions can help.

Our Blog

Heat Pipe Considerations For Distance

For most, knowing which thermal solutions to utilize in order to receive the best possible outcomes can be a difficult process. Not only do you have to look at and compare the functions of several heat exchangers, but you have to recognize how your own parameters and needs factor into use. In other words, it is common for groups to invest in a heat exchanger without knowing the full depth to function, and oftentimes, these devices function below capacity if the company’s parameters are not considered. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX looks at the benefits of heat pipe thermal management, including its ability to provide effective cooling over a distance.

For most, knowing which thermal solutions to utilize in order to receive the best possible outcomes can be a difficult process. Not only do you have to look at and compare the functions of several heat exchangers, but you have to recognize how your own parameters and needs factor into use. In other words, it is common for groups to invest in a heat exchanger without knowing the full depth to function, and oftentimes, these devices function below capacity if the company’s parameters are not considered. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX looks at the benefits of heat pipe thermal management, including its ability to provide effective cooling over a distance.

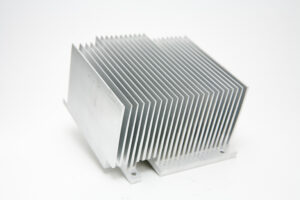

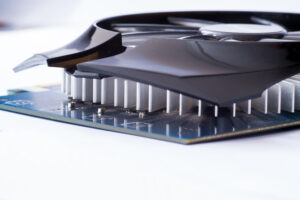

Application Cooling With Heat Sinks

In our most recent blog post, we took a look at the importance of thermal management capabilities and how it is essential for optimal function of all technological applications. Indeed, many devices are not created initially with the ability to rid their enclosures of waste heat, and as a result, the waste energy accumulates until internal temperatures reach dangerous levels during operation. As a result, shutdowns, overheating, and even electrical fires can occur. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses ways that heat sink heat exchangers can address these issues, as well as how your applications can benefit from thermal dissipation.

In our most recent blog post, we took a look at the importance of thermal management capabilities and how it is essential for optimal function of all technological applications. Indeed, many devices are not created initially with the ability to rid their enclosures of waste heat, and as a result, the waste energy accumulates until internal temperatures reach dangerous levels during operation. As a result, shutdowns, overheating, and even electrical fires can occur. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses ways that heat sink heat exchangers can address these issues, as well as how your applications can benefit from thermal dissipation.

What To Know About Thermal Management

Technological advancement has made it possible to accomplish greater levels of productivity in addition to producing greater outcomes. Indeed, it is important to consider the different needs of each industry when measuring success, and having a plethora of methods on hand to address these needs is even more essential when aiming to optimize a company’s technological capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the need for regular thermal management, as well as how our team can help set you up with a custom thermal solution to optimize your capabilities.

Technological advancement has made it possible to accomplish greater levels of productivity in addition to producing greater outcomes. Indeed, it is important to consider the different needs of each industry when measuring success, and having a plethora of methods on hand to address these needs is even more essential when aiming to optimize a company’s technological capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the need for regular thermal management, as well as how our team can help set you up with a custom thermal solution to optimize your capabilities.

Addressing Your Needs With Different Methods

It goes without saying that your industrial application’s needs are just as individual as you are. Whether you are working in an industry where extreme conditions are a constant, or you simply require a quality heat exchanger to prevent overheating in material processing, it is important to consider your needs and parameters in the process. In fact, no solution can optimize your capabilities unless it factors in your parameters. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the process of determining thermal management methods to help optimize your capabilities, as well as how our team can help.

It goes without saying that your industrial application’s needs are just as individual as you are. Whether you are working in an industry where extreme conditions are a constant, or you simply require a quality heat exchanger to prevent overheating in material processing, it is important to consider your needs and parameters in the process. In fact, no solution can optimize your capabilities unless it factors in your parameters. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the process of determining thermal management methods to help optimize your capabilities, as well as how our team can help.

Plastic Mold Cooling For Material Processing

In industries such as material processing where cycle times and consistent cooling are a must, a custom heat exchanger such as a thermal pin can be of great use. Indeed, many companies utilize plastic cooling capabilities in order to create a host of items to house or package their primary goods, whereas others operate solely for the production of plastic bins, containers, and other items. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX investigates the need for consistent cooling capabilities in material processing and how our thermal pin heat exchangers can help.

In industries such as material processing where cycle times and consistent cooling are a must, a custom heat exchanger such as a thermal pin can be of great use. Indeed, many companies utilize plastic cooling capabilities in order to create a host of items to house or package their primary goods, whereas others operate solely for the production of plastic bins, containers, and other items. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX investigates the need for consistent cooling capabilities in material processing and how our thermal pin heat exchangers can help.

Thermal Methods Using The Peltier Effect

For the past few weeks, our main site has been going through the various industries that our products can assist in, including everything ranging from wastewater treatment to Power to even Food & Beverage packaging. Meanwhile, on our CTS end, we have begun discussing the methods to the process, if you will, as well as exploring the different applications that could benefit from the means. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the processes behind thermoelectric cooling and how solutions of this nature can assist in your technological capabilities.

For the past few weeks, our main site has been going through the various industries that our products can assist in, including everything ranging from wastewater treatment to Power to even Food & Beverage packaging. Meanwhile, on our CTS end, we have begun discussing the methods to the process, if you will, as well as exploring the different applications that could benefit from the means. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the processes behind thermoelectric cooling and how solutions of this nature can assist in your technological capabilities.

Looking At Phase-Change Cooling

It goes without saying that there are several different ways to get to a single conclusion or result. This notion is true for a variety of circumstances, including finding solutions for optimal thermal management. Indeed, application cooling can occur as a result of passive or active convective heat transfer, thermoelectric means, and even through the use of phase-change technology. Still, not every method is ideal for your needs, and our team is ready to help you determine the best course of action to achieve your goals. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a more detailed look at the way phase-change technology works and how it is used in various applications.

It goes without saying that there are several different ways to get to a single conclusion or result. This notion is true for a variety of circumstances, including finding solutions for optimal thermal management. Indeed, application cooling can occur as a result of passive or active convective heat transfer, thermoelectric means, and even through the use of phase-change technology. Still, not every method is ideal for your needs, and our team is ready to help you determine the best course of action to achieve your goals. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a more detailed look at the way phase-change technology works and how it is used in various applications.

Forced Cooling Through Convective Transfer

In our most recent blog post, we took a look at the way convective heat transfer utilizes passive cooling methods in order to provide adequate temperature regulation within an industrial application. Although passive methods can certainly streamline a company’s technological capabilities, it is important to note that not all applications can benefit optimally from such methods. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways active convective heat transfer utilizes forced movement to promote optimal function.

In our most recent blog post, we took a look at the way convective heat transfer utilizes passive cooling methods in order to provide adequate temperature regulation within an industrial application. Although passive methods can certainly streamline a company’s technological capabilities, it is important to note that not all applications can benefit optimally from such methods. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways active convective heat transfer utilizes forced movement to promote optimal function.

Have You Heard Of Passive Heat Transfer?

Recently, we have been exploring the many stages of the thermal solution design process. Thus far, we have looked at the role of customization in the design phase, why we prototype prior to manufacturing, the emphasis we place on collaborative engineering, and how we oversee this entire manufacturing process from start to finish. In addition to the process, it is important to know which thermal methods to use for which industrial applications, and not all heat exchangers are created the same. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the function of passive heat transfer in many of our products, as well as which devices may benefit most from these methods.

Recently, we have been exploring the many stages of the thermal solution design process. Thus far, we have looked at the role of customization in the design phase, why we prototype prior to manufacturing, the emphasis we place on collaborative engineering, and how we oversee this entire manufacturing process from start to finish. In addition to the process, it is important to know which thermal methods to use for which industrial applications, and not all heat exchangers are created the same. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the function of passive heat transfer in many of our products, as well as which devices may benefit most from these methods.