Having the capabilities to work out potential flaws and issues in a design early on helps save you time and cost. Indeed, rapid prototyping capabilities can help you acquire a thermal solution better customized to your needs, but failing to consider the role methods play in the process can negatively influence your business’ productivity and competition. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the eco-friendly and sustainable methods we use to help you get the most from your thermal management capabilities.

Having the capabilities to work out potential flaws and issues in a design early on helps save you time and cost. Indeed, rapid prototyping capabilities can help you acquire a thermal solution better customized to your needs, but failing to consider the role methods play in the process can negatively influence your business’ productivity and competition. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the eco-friendly and sustainable methods we use to help you get the most from your thermal management capabilities.

Our Blog

Benefits of Rapid Prototyping

It goes without saying that, in order to streamline your operational process, you must first have a thorough understanding of your application’s parameters. Indeed, your processes can only function as well as your equipment and ignoring the environmental and other factors that influence this process is detrimental to your operation overall. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the process we utilize when manufacturing your custom thermal solutions, and how rapid prototyping saves you money in the long run.

It goes without saying that, in order to streamline your operational process, you must first have a thorough understanding of your application’s parameters. Indeed, your processes can only function as well as your equipment and ignoring the environmental and other factors that influence this process is detrimental to your operation overall. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the process we utilize when manufacturing your custom thermal solutions, and how rapid prototyping saves you money in the long run.

What To Consider For Optimal Function

Your technological applications help you accomplish so much when it comes to business operation and production. After all, a machine or system of machines can streamline tasks to produce a much higher yield than humanly possible for an individual, allowing for more in terms of profit and productivity. In order to get the most from your applications, however, you must first have a thorough understanding of your parameters and their potential limits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at what you should consider when seeking improved thermal function, as well as how our team can help.

Your technological applications help you accomplish so much when it comes to business operation and production. After all, a machine or system of machines can streamline tasks to produce a much higher yield than humanly possible for an individual, allowing for more in terms of profit and productivity. In order to get the most from your applications, however, you must first have a thorough understanding of your parameters and their potential limits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at what you should consider when seeking improved thermal function, as well as how our team can help.

The Science Of Heat Pipe Thermal Management

By now you are likely familiar with the concept of overheating. It occurs to humans when we run too long without some form of a break or method to cool us down, and it also occurs in technological applications. You see, as an application continues to function, waste heat is produced, causing internal temperatures to rise. This can lead to a number of complications, which is why it is important to utilize an effective form of management.

By now you are likely familiar with the concept of overheating. It occurs to humans when we run too long without some form of a break or method to cool us down, and it also occurs in technological applications. You see, as an application continues to function, waste heat is produced, causing internal temperatures to rise. This can lead to a number of complications, which is why it is important to utilize an effective form of management.

Still, however, how can you determine the optimal solution when many exist? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the importance of the methods we use in our products, as well as how heat pipes can help streamline your operation.

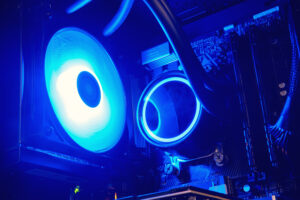

Benefits From Active Cooling Capabilities

In a world where production is king and the majority of businesses depend heavily on equipment that streamlines productivity, the last thing any business owner needs to endure includes the troubles of breaking down technology. Indeed, it would be foolish to believe that our machines will continue to function without paying mind to their needs, and cutting corners will inevitably end up costing you significantly in the end. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at why thermal management is essential to production, and how active cooling capabilities can help.

In a world where production is king and the majority of businesses depend heavily on equipment that streamlines productivity, the last thing any business owner needs to endure includes the troubles of breaking down technology. Indeed, it would be foolish to believe that our machines will continue to function without paying mind to their needs, and cutting corners will inevitably end up costing you significantly in the end. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at why thermal management is essential to production, and how active cooling capabilities can help.

Thermal Solutions For Military Equipment

It goes without saying that there are many methods that can be used to ensure application cooling within your industrial equipment, but not all methods are efficient, per se. Indeed, some options lead to higher function at a greater cost to the environment, whereas others may prioritize eco-friendly methods while letting your productivity fall flat. With that in mind, how do you find the sweet spot where an application can function at capacity without causing significant harm to the environment? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at this question with respect to military-grade equipment, and how our ruggedized methods can help.

It goes without saying that there are many methods that can be used to ensure application cooling within your industrial equipment, but not all methods are efficient, per se. Indeed, some options lead to higher function at a greater cost to the environment, whereas others may prioritize eco-friendly methods while letting your productivity fall flat. With that in mind, how do you find the sweet spot where an application can function at capacity without causing significant harm to the environment? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at this question with respect to military-grade equipment, and how our ruggedized methods can help.

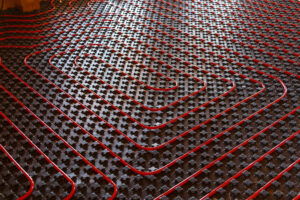

Natural Methods For Enclosure Cooling

There are a variety of options that exist when it comes to thermal management, but keep in mind that not all of them are ideal. Indeed, some heat exchangers may be able to initiate rapid cooling, but sometimes it may come at the cost of your working and/or physical environment. On the other hand, eco-friendly options exist, but they may not function as ideally as intended when working in a competitive market. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss how our heat pipe heat exchangers combine the best of both worlds to help you achieve ideal heat pipe enclosure cooling.

There are a variety of options that exist when it comes to thermal management, but keep in mind that not all of them are ideal. Indeed, some heat exchangers may be able to initiate rapid cooling, but sometimes it may come at the cost of your working and/or physical environment. On the other hand, eco-friendly options exist, but they may not function as ideally as intended when working in a competitive market. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss how our heat pipe heat exchangers combine the best of both worlds to help you achieve ideal heat pipe enclosure cooling.

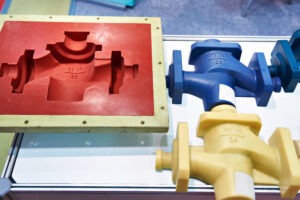

What To Know About Plastic Mold Cooling

When everything is functioning smoothly, you can count on increased yields, reduced cycle times, and more. From time to time, however, you may endure mechanical breakdown, application overheating, and a variety of other concerns that can significantly impact or halt productivity altogether. Though this phenomenon may not occur frequently, the truth of the matter is that it may just be enough to hold up production and cost your company significantly. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX examines how this phenomenon affects the plastic mold industry, and how custom thermal solutions can help.

When everything is functioning smoothly, you can count on increased yields, reduced cycle times, and more. From time to time, however, you may endure mechanical breakdown, application overheating, and a variety of other concerns that can significantly impact or halt productivity altogether. Though this phenomenon may not occur frequently, the truth of the matter is that it may just be enough to hold up production and cost your company significantly. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX examines how this phenomenon affects the plastic mold industry, and how custom thermal solutions can help.

Optimal Function With Thermal Accessories

It goes without saying that a major part of staying ahead of the curve in a competitive field is having your operation’s function and process down to a science. Indeed, consistent and dependable function propels businesses significantly forward, whereas inconsistent function and frequent breakdowns can end up costing companies significantly in terms of money. While some organizations may need an entirely new method for thermal management, however, others may only require the assistance of an accessory to do so. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the function of our major accessories, and how we will work with you to achieve the level of cooling you deserve.

It goes without saying that a major part of staying ahead of the curve in a competitive field is having your operation’s function and process down to a science. Indeed, consistent and dependable function propels businesses significantly forward, whereas inconsistent function and frequent breakdowns can end up costing companies significantly in terms of money. While some organizations may need an entirely new method for thermal management, however, others may only require the assistance of an accessory to do so. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the function of our major accessories, and how we will work with you to achieve the level of cooling you deserve.

Effective Cooling In Tight Spaces

Not every industrial setup is ideal for effective thermal management, especially when it is designed to utilize only a base-level product. Indeed, your applications and equipment help elevate your capabilities but bear in mind that it is important to be aware of your equipment’s needs in order to ensure it can operate to its full capacity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses solutions that regulate internal temperatures even when working with minimal space, as well as how a liquid cold plate can help.

Not every industrial setup is ideal for effective thermal management, especially when it is designed to utilize only a base-level product. Indeed, your applications and equipment help elevate your capabilities but bear in mind that it is important to be aware of your equipment’s needs in order to ensure it can operate to its full capacity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses solutions that regulate internal temperatures even when working with minimal space, as well as how a liquid cold plate can help.