The need for maintenance and care when it comes to your industrial applications is something you do not want to leave on the back burner. Indeed, the key to ideal function within the equipment your business so heavily relies on is to ensure the parameters surrounding it are addressed and taken care of, which means seeking alternate ways to regulate internal temperature. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the science behind one of our more popular thermal management solutions – the heat sink – and explains the benefits of upgrading your capabilities.

The need for maintenance and care when it comes to your industrial applications is something you do not want to leave on the back burner. Indeed, the key to ideal function within the equipment your business so heavily relies on is to ensure the parameters surrounding it are addressed and taken care of, which means seeking alternate ways to regulate internal temperature. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the science behind one of our more popular thermal management solutions – the heat sink – and explains the benefits of upgrading your capabilities.

Our Blog

Cooling Through Thermoelectric Junctions

It goes without saying that by and large, thermal regulation is one of the most important considerations to make when it comes to your technological applications. Indeed, any sort of mechanical or chemical action will result in the production of waste heat, and as such, this waste energy will only continue to increase once it develops. As a result, an effective solution is needed in order to ensure your applications are running as they should be. But how is this accomplished? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind thermoelectric thermal management, as well as how your applications benefit from these practices.

It goes without saying that by and large, thermal regulation is one of the most important considerations to make when it comes to your technological applications. Indeed, any sort of mechanical or chemical action will result in the production of waste heat, and as such, this waste energy will only continue to increase once it develops. As a result, an effective solution is needed in order to ensure your applications are running as they should be. But how is this accomplished? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind thermoelectric thermal management, as well as how your applications benefit from these practices.

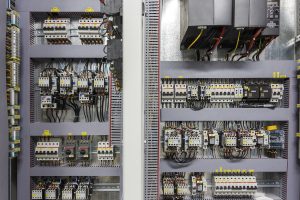

Protective Options For Sensitive Electronics

There are countless industries out there nowadays that rely heavily on the equipment they use to keep the line up and moving. For instance, Oil & Gas equipment must be able to withstand tough conditions and extremes in environments, just as the technology used in the plastic molding industry must be able to consistently cool its internal temperatures so as to prevent overheating and promote reliable production. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at fields that utilize electrical enclosures to protect sensitive electronics, and how our custom thermal solutions can help.

There are countless industries out there nowadays that rely heavily on the equipment they use to keep the line up and moving. For instance, Oil & Gas equipment must be able to withstand tough conditions and extremes in environments, just as the technology used in the plastic molding industry must be able to consistently cool its internal temperatures so as to prevent overheating and promote reliable production. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at fields that utilize electrical enclosures to protect sensitive electronics, and how our custom thermal solutions can help.

Dependability For Oil & Gas Applications

It goes without saying that, in order to get the most out of your technological applications, you will need to ensure they have everything they need to operate efficiently and smoothly. This means knowing which thermal management solutions are more ideal for the equipment in use, as well as taking into consideration a number of parameters surrounding your operation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the needs of oil and gas applications, as well as what oil and gas enclosure cooling looks like for your company.

It goes without saying that, in order to get the most out of your technological applications, you will need to ensure they have everything they need to operate efficiently and smoothly. This means knowing which thermal management solutions are more ideal for the equipment in use, as well as taking into consideration a number of parameters surrounding your operation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the needs of oil and gas applications, as well as what oil and gas enclosure cooling looks like for your company.

Ambient Methods For Application Cooling

Thermal management is a necessary consideration to make when operating industrial applications in your line of work. Indeed, just as a person sprinting in the hot summer sun can become fatigued, so can your devices. As such, it is important to ensure there are methods in play that can regulate internal temperatures. These can range in terms of exact offerings and benefits, and your needs should be assessed before purchasing the next one-size-fits-all solution. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways ambient methods can lead to effective filter fan enclosure cooling.

Thermal management is a necessary consideration to make when operating industrial applications in your line of work. Indeed, just as a person sprinting in the hot summer sun can become fatigued, so can your devices. As such, it is important to ensure there are methods in play that can regulate internal temperatures. These can range in terms of exact offerings and benefits, and your needs should be assessed before purchasing the next one-size-fits-all solution. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the ways ambient methods can lead to effective filter fan enclosure cooling.

Versatility of Heat Pipe Thermal Solutions

Even though there are a number of striking differences in function when it comes to a variety of different industrial applications, one thing that will always need to be considered or addressed is the device’s thermal management processes. Indeed, many machines do not come with built-in temperature control or regulation, and as such, require a heat exchanger that is able to remove waste heat. But what are your options, and what will work best for your devices? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the versatility behind heat pipe assemblies, and how they utilize a minimal amount of space while providing optimal thermal management.

Even though there are a number of striking differences in function when it comes to a variety of different industrial applications, one thing that will always need to be considered or addressed is the device’s thermal management processes. Indeed, many machines do not come with built-in temperature control or regulation, and as such, require a heat exchanger that is able to remove waste heat. But what are your options, and what will work best for your devices? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the versatility behind heat pipe assemblies, and how they utilize a minimal amount of space while providing optimal thermal management.

What Is An Air To Water Heat Exchanger?

It goes without saying that there are a variety of methods to ensure adequate thermal management within your technological applications, and how effective these methods are will vary from industry to industry. Indeed, the most ideal solution is not always the most complex, and there are a variety of natural methods that can be used to effectively cool overheating applications without sacrificing quality and optimal function. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how an air to water heat exchanger functions, as well as how our team can help throughout the process.

It goes without saying that there are a variety of methods to ensure adequate thermal management within your technological applications, and how effective these methods are will vary from industry to industry. Indeed, the most ideal solution is not always the most complex, and there are a variety of natural methods that can be used to effectively cool overheating applications without sacrificing quality and optimal function. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how an air to water heat exchanger functions, as well as how our team can help throughout the process.

Custom Air To Air Thermal Solutions

Air to air enclosure cooling may differ from methods that utilize water – such as heat pipes and other phase-change technologies – but they can be used in a variety of different industrial applications. Indeed, whether you are trying to initiate cooling in your electrical enclosure or remove waste heat through dissipation, air to air enclosure cooling can be customized to meet your unique needs. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses what it means to implement an air-to-air method, and how simpler solutions can yield optimal results.

Air to air enclosure cooling may differ from methods that utilize water – such as heat pipes and other phase-change technologies – but they can be used in a variety of different industrial applications. Indeed, whether you are trying to initiate cooling in your electrical enclosure or remove waste heat through dissipation, air to air enclosure cooling can be customized to meet your unique needs. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses what it means to implement an air-to-air method, and how simpler solutions can yield optimal results.

Considerations For Electrical Enclosures

Though thermal management should be a consideration for all industrial applications, all too often, there are no appropriate ways for equipment to expel waste heat. As a result, the internal temperatures will continue to rise until they reach dangerous levels, resulting in application failure, breakdown, and permanent damage. What’s more? The sensitive electronics such as wires and more that are contained within panels can cause electrical fires, making the situation significantly worse. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how a custom heat exchanger can help regulate internal temperatures in applications, providing effective electrical panel enclosure cooling.

Though thermal management should be a consideration for all industrial applications, all too often, there are no appropriate ways for equipment to expel waste heat. As a result, the internal temperatures will continue to rise until they reach dangerous levels, resulting in application failure, breakdown, and permanent damage. What’s more? The sensitive electronics such as wires and more that are contained within panels can cause electrical fires, making the situation significantly worse. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how a custom heat exchanger can help regulate internal temperatures in applications, providing effective electrical panel enclosure cooling.

What Is HazLoc Enclosure Cooling?

Equipment and technological advancement have paved the way for virtually every industry, as now tasks and functions are able to be accomplished at a much more rapid and consistent rate. Indeed, this fares well for businesses that operate in a competitive market, and it also helps ensure that operations are cost-effective. Still, however, devices that do not consider specific needs and parameters of a particular business will not fare as well as those that do, and this could end up costing a company significantly in terms of profit and safety.

Equipment and technological advancement have paved the way for virtually every industry, as now tasks and functions are able to be accomplished at a much more rapid and consistent rate. Indeed, this fares well for businesses that operate in a competitive market, and it also helps ensure that operations are cost-effective. Still, however, devices that do not consider specific needs and parameters of a particular business will not fare as well as those that do, and this could end up costing a company significantly in terms of profit and safety.

In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at specific needs that must be met to provide effective application cooling, and how we create heat exchangers that can withstand hazardous conditions.