Effective heat management can best be accomplished through a number of methods. In fact, each application in each industry has a unique set of needs and parameters to be met, and yours is no exception. Indeed, some equipment needs an entirely new and updated method for effective cooling, meanwhile, others only require a small accessory to boost productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to discuss the ways that filter fan enclosure cooling can benefit your company.

Effective heat management can best be accomplished through a number of methods. In fact, each application in each industry has a unique set of needs and parameters to be met, and yours is no exception. Indeed, some equipment needs an entirely new and updated method for effective cooling, meanwhile, others only require a small accessory to boost productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to discuss the ways that filter fan enclosure cooling can benefit your company.

Our Blog

Understanding Passive and Active Heat Transfer

When it comes to the needs of your technological applications, venturing on the side of quality solutions is always the better option than seeking assistance from products that barely get the job done. What’s more, the switch from uniform products to those of custom creation has played a major role in the transition of goals from overcoming overheating to accomplishing that in addition to efficiency. This is also in large part due to a number of useful methods and technologies. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to discuss one of those technologies in particular – passive and active heat transfer – and explain the way it accomplishes effective temperature regulation.

When it comes to the needs of your technological applications, venturing on the side of quality solutions is always the better option than seeking assistance from products that barely get the job done. What’s more, the switch from uniform products to those of custom creation has played a major role in the transition of goals from overcoming overheating to accomplishing that in addition to efficiency. This is also in large part due to a number of useful methods and technologies. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to discuss one of those technologies in particular – passive and active heat transfer – and explain the way it accomplishes effective temperature regulation.

Ideal Application Cooling With Various Solutions

We have said it before and we will say it again: one-size-fits all solutions are a thing of the past. As technology continues to innovate, develop, and expand, so do the machines and applications that fields use to ensure proper function and productivity. While each application shares a similar need in that overheating must be addressed so as not to damage sensitive electronics, the methods utilized to accomplish this goal vary as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the ways that we create various products to assist in your plight to cool your technological applications effectively.

We have said it before and we will say it again: one-size-fits all solutions are a thing of the past. As technology continues to innovate, develop, and expand, so do the machines and applications that fields use to ensure proper function and productivity. While each application shares a similar need in that overheating must be addressed so as not to damage sensitive electronics, the methods utilized to accomplish this goal vary as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the ways that we create various products to assist in your plight to cool your technological applications effectively.

Eco-Friendly Solutions With Phase-Change Technology

Whether you are in the material processing field, Waste Water Management, or anything in-between, you likely rely heavily on advanced equipment to streamline production. That being said, you also rely on effective thermal management capabilities to ensure that your equipment does not overheat and continues to function optimally. What’s more, there are a number of considerations to account for to ensure the best solution, including working environment, cost or depth of maintenance, and so on. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at the manner in which we achieve eco-friendly resolutions with the help of phase-change technology.

Whether you are in the material processing field, Waste Water Management, or anything in-between, you likely rely heavily on advanced equipment to streamline production. That being said, you also rely on effective thermal management capabilities to ensure that your equipment does not overheat and continues to function optimally. What’s more, there are a number of considerations to account for to ensure the best solution, including working environment, cost or depth of maintenance, and so on. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at the manner in which we achieve eco-friendly resolutions with the help of phase-change technology.

Better Thermal Management In A Material Processing Operation

Faster output and higher quality production both have clear appeal to any material processing operation. If you are looking for a way to make meaningful improvements to your operations, take time to look at your current approach to better thermal management. A customized approach to plastic mold cooling can boost cycle times while also making it easier to produce better products. At Noren Thermal Solutions, we provide customized thermal solutions for a range of industries. By collaborating with our clients, we are able to provide personalized solutions that lead to more efficiency and better production value.

Faster output and higher quality production both have clear appeal to any material processing operation. If you are looking for a way to make meaningful improvements to your operations, take time to look at your current approach to better thermal management. A customized approach to plastic mold cooling can boost cycle times while also making it easier to produce better products. At Noren Thermal Solutions, we provide customized thermal solutions for a range of industries. By collaborating with our clients, we are able to provide personalized solutions that lead to more efficiency and better production value.

(more…)

Customization Through Heat Pipe Variety

Before efficiency was a top priority of custom thermal management, the main purpose of air-to-air solutions was to ensure that a variety of technological applications and sensitive electronic did not overheat. As time moved on, innovators in the field looked to methods of effective temperature regulation that not only prioritized cooling equipment, but doing so in a manner that optimized production and yield. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX expand upon this idea by discussing the ways that heat pipe installations allow for customization and variety.

Before efficiency was a top priority of custom thermal management, the main purpose of air-to-air solutions was to ensure that a variety of technological applications and sensitive electronic did not overheat. As time moved on, innovators in the field looked to methods of effective temperature regulation that not only prioritized cooling equipment, but doing so in a manner that optimized production and yield. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX expand upon this idea by discussing the ways that heat pipe installations allow for customization and variety.

Optimal Performance For Air To Air Thermal Management

Technology has and continues to make a number of processes much more streamlined and simpler than ever before. In fact, a number of industries rely heavily on advanced applications to perform varying tasks, from production and increased yields to effective treatment. Keep in mind, however, a machine is only going to work as well as it is maintenance and treated, and failure to optimize its thermal management capabilities can cost you greatly in the long-run. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX looks at accomplishing this task using advanced methods to make air-to-air temperature regulation more efficient.

Technology has and continues to make a number of processes much more streamlined and simpler than ever before. In fact, a number of industries rely heavily on advanced applications to perform varying tasks, from production and increased yields to effective treatment. Keep in mind, however, a machine is only going to work as well as it is maintenance and treated, and failure to optimize its thermal management capabilities can cost you greatly in the long-run. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX looks at accomplishing this task using advanced methods to make air-to-air temperature regulation more efficient.

What It Means To Use Eco-Friendly Technology

Making sure that your technological applications are functioning properly is imperative to ensuring a productive yield and efficient working environment. Indeed, the use of thermal management concepts make temperature regulation within this equipment much more sustainable as well as optimizes output. That being said, are most solutions truly ideal for outside factors, including the environment? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the manner in which we design all of our products with eco-friendliness in mind.

Making sure that your technological applications are functioning properly is imperative to ensuring a productive yield and efficient working environment. Indeed, the use of thermal management concepts make temperature regulation within this equipment much more sustainable as well as optimizes output. That being said, are most solutions truly ideal for outside factors, including the environment? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the manner in which we design all of our products with eco-friendliness in mind.

How Thermal Management Concepts Work

It is no surprise that technology has played and continues to play a major role in a variety of industries, especially with rapid advancements and a greater spread of possibilities. Products such as the manufacturing line, oil rigs, and much more have exponentially influenced our level of productivity as a whole. When it comes to maintaining these devices, however, there is little room for error in ensuring optimal function. In today’s log, the team at Noren Thermal Solutions in Taylor, TX will look at the ways in which we accomplish effective temperature regulation by explaining the science behind our thermal management concepts.

It is no surprise that technology has played and continues to play a major role in a variety of industries, especially with rapid advancements and a greater spread of possibilities. Products such as the manufacturing line, oil rigs, and much more have exponentially influenced our level of productivity as a whole. When it comes to maintaining these devices, however, there is little room for error in ensuring optimal function. In today’s log, the team at Noren Thermal Solutions in Taylor, TX will look at the ways in which we accomplish effective temperature regulation by explaining the science behind our thermal management concepts.

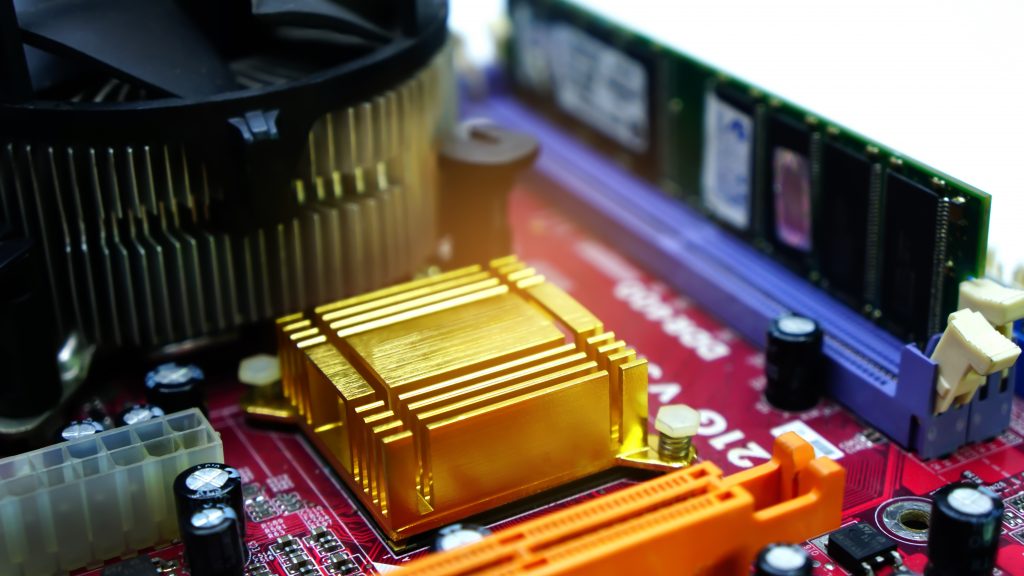

How Does A Heat Sink Function?

Having an understanding of thermal management concepts goes a long way when it comes to ensuring optimal function. In fact, a variety of methods can be used to accomplish such as feat, including conduction, convection, and radiation. What’s more, understanding the roles these methods play in energy spreading, movement, and dissipation is the key to a successful production. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take an in-depth look at the way specific products such as heat sinks utilize dissipation in order to promote proper temperature regulation.

Having an understanding of thermal management concepts goes a long way when it comes to ensuring optimal function. In fact, a variety of methods can be used to accomplish such as feat, including conduction, convection, and radiation. What’s more, understanding the roles these methods play in energy spreading, movement, and dissipation is the key to a successful production. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take an in-depth look at the way specific products such as heat sinks utilize dissipation in order to promote proper temperature regulation.