Thermal management and regulation are essential factors to consider if you are relying on technology to perform routine tasks. Following the boom of technological advancement, most major players in their industries implemented the use of industrial applications. This process not only allowed for exponentially faster cycle time, but increased yield production as well. Still, there is always room for improvement, and optimizing your heat transfer process can help. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses ways in which you can get the most from your machines and how our team can help.

Thermal management and regulation are essential factors to consider if you are relying on technology to perform routine tasks. Following the boom of technological advancement, most major players in their industries implemented the use of industrial applications. This process not only allowed for exponentially faster cycle time, but increased yield production as well. Still, there is always room for improvement, and optimizing your heat transfer process can help. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses ways in which you can get the most from your machines and how our team can help.

Our Blog

Higher Quality Through Collaborative Engineering

As an industry that strives to produce high-quality products, your cycle times, applications, and team overall are important factors to consider. After all, these features, among others, all factor into your ability to perform any given task to meet a high demand, meaning there is seldom room for error. Indeed, a one-size-fits-all heat exchanger may sound appealing initially, but it won’t be long before you endure complications as a result of non-specific methods. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how our team utilizes collaborative engineering to ensure your custom thermal solution meets your needs precisely and allows you to get the most from your applications.

As an industry that strives to produce high-quality products, your cycle times, applications, and team overall are important factors to consider. After all, these features, among others, all factor into your ability to perform any given task to meet a high demand, meaning there is seldom room for error. Indeed, a one-size-fits-all heat exchanger may sound appealing initially, but it won’t be long before you endure complications as a result of non-specific methods. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how our team utilizes collaborative engineering to ensure your custom thermal solution meets your needs precisely and allows you to get the most from your applications.

High-Performance Plastic Processing

It goes without saying that getting the most from your thermal applications depends heavily on the methods used to ensure proper cooling. Indeed, just as a person may become exhausted or fatigued from consistent running without a break, your applications can be influenced by various factors that result in system breakdown, electrical fires, and more. While it may seem as though the solution is to find accessories that benefit your devices, this is not always as easy as it seems. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX identifies important roles of high-performance solutions for material processing, as well as how our team can help.

It goes without saying that getting the most from your thermal applications depends heavily on the methods used to ensure proper cooling. Indeed, just as a person may become exhausted or fatigued from consistent running without a break, your applications can be influenced by various factors that result in system breakdown, electrical fires, and more. While it may seem as though the solution is to find accessories that benefit your devices, this is not always as easy as it seems. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX identifies important roles of high-performance solutions for material processing, as well as how our team can help.

Why Rapid Prototyping Is Essential

Prototypes are an essential part of the production process. It allows a manufacturer to build and then assess the compatibility of an item in a realistic environment before spending more time and money on creating a fully-functioning end product. This is especially true when it comes to crafting custom thermal management solutions. When you need reliable, specialized cooling products, you need to be sure they work exactly as intended — especially if they are custom-made for your existing machinery. You also can’t put your production on hold, which is why rapid prototyping is so important. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the myriad benefits of rapid prototyping and how we can deliver custom products with a quick turnaround time. (more…)

Prototypes are an essential part of the production process. It allows a manufacturer to build and then assess the compatibility of an item in a realistic environment before spending more time and money on creating a fully-functioning end product. This is especially true when it comes to crafting custom thermal management solutions. When you need reliable, specialized cooling products, you need to be sure they work exactly as intended — especially if they are custom-made for your existing machinery. You also can’t put your production on hold, which is why rapid prototyping is so important. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the myriad benefits of rapid prototyping and how we can deliver custom products with a quick turnaround time. (more…)

Considerations For Ideal Wastewater Care

Various industries undergo upgrades to their equipment and changes regularly to stay on top of the growing demand within their respective fields. This can be seen in demand for consistent application function, as well as a prominent need for prevention when it comes to overheating. Indeed, most companies rely heavily on their applications’ capabilities, and ensuring you utilize the correct method for your parameters is essential. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the major considerations to keep in mind for wastewater care, and how our team can help.

Various industries undergo upgrades to their equipment and changes regularly to stay on top of the growing demand within their respective fields. This can be seen in demand for consistent application function, as well as a prominent need for prevention when it comes to overheating. Indeed, most companies rely heavily on their applications’ capabilities, and ensuring you utilize the correct method for your parameters is essential. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the major considerations to keep in mind for wastewater care, and how our team can help.

Safe Practices With Two-Phase Solutions

It is no longer acceptable to “just get by” in terms of your application’s function. While one-size-fits-all products of the past helped promote consistent function, we have now seen a rise in competition and the need for efficient solutions. This extends to your operation, regardless of industry. While some competitors may tout the ability to provide a better use out of your devices, they may come at a price. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at our use of two-phase methods, and how utilizing a fluids latent point of vaporization can provide safe and sustainable options in various industries.

It is no longer acceptable to “just get by” in terms of your application’s function. While one-size-fits-all products of the past helped promote consistent function, we have now seen a rise in competition and the need for efficient solutions. This extends to your operation, regardless of industry. While some competitors may tout the ability to provide a better use out of your devices, they may come at a price. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at our use of two-phase methods, and how utilizing a fluids latent point of vaporization can provide safe and sustainable options in various industries.

Quality Results With Below Ambient Cooling

In order to ensure proper application function, an understanding of the way your physical environment influences functional capabilities is necessary. For example, you might not immediately recognize that your working environment’s temperature can cause an application to overheat at a rapid rate, and it is for this reason that you must consider this and other factors when planning your company’s operation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a closer look at the way below ambient cooling capabilities can provide consistent temperature regulation for various electrical cabinets, as well as how customization elevates the process.

In order to ensure proper application function, an understanding of the way your physical environment influences functional capabilities is necessary. For example, you might not immediately recognize that your working environment’s temperature can cause an application to overheat at a rapid rate, and it is for this reason that you must consider this and other factors when planning your company’s operation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a closer look at the way below ambient cooling capabilities can provide consistent temperature regulation for various electrical cabinets, as well as how customization elevates the process.

Utilizing Thermal Dissipation Practices

Being able to utilize your industrial applications to their full capacity is a feat many individuals are unable to accomplish. What’s more? Most of this population may not even be aware of this issue, or the fact that it could be costing them significantly over time. Unfortunately, this is true for most industries that utilize one-size-fits-all thermal management products, and paying attention to your unique needs and parameters can work wonders. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a closer look at the science behind heat sink thermal management, and how heat dissipation offers a more sustainable method of transfer.

Being able to utilize your industrial applications to their full capacity is a feat many individuals are unable to accomplish. What’s more? Most of this population may not even be aware of this issue, or the fact that it could be costing them significantly over time. Unfortunately, this is true for most industries that utilize one-size-fits-all thermal management products, and paying attention to your unique needs and parameters can work wonders. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a closer look at the science behind heat sink thermal management, and how heat dissipation offers a more sustainable method of transfer.

Custom Thermal Pin Heat Exchangers

It goes without saying that your technological applications are an essential component to productivity and production as a whole. As a matter of fact, could you even imagine operating consistently without the help of your equipment? It would certainly complicate the process, and in order to avoid these concerns, you must be vigilant about the circumstances and factors that could influence your capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX addresses the importance of consistency and dependability in the plastic injection mold cooling industry, and how a custom heat exchanger can help.

It goes without saying that your technological applications are an essential component to productivity and production as a whole. As a matter of fact, could you even imagine operating consistently without the help of your equipment? It would certainly complicate the process, and in order to avoid these concerns, you must be vigilant about the circumstances and factors that could influence your capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX addresses the importance of consistency and dependability in the plastic injection mold cooling industry, and how a custom heat exchanger can help.

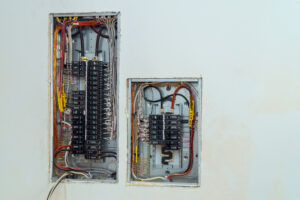

Protecting Sensitive Wires Consistently

Technological advancement has made it possible to perform various tasks at an exponentially faster rate than was previously possible. Due to these advantages, most – if not all – companies took strides to upgrade their equipment and capabilities. From wastewater treatment to power management and virtually every industry in-between, industrial applications have proven a significant improvement. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance of maintaining internal temperatures within your applications, and how we can help protect sensitive electronics consistently.

Technological advancement has made it possible to perform various tasks at an exponentially faster rate than was previously possible. Due to these advantages, most – if not all – companies took strides to upgrade their equipment and capabilities. From wastewater treatment to power management and virtually every industry in-between, industrial applications have proven a significant improvement. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance of maintaining internal temperatures within your applications, and how we can help protect sensitive electronics consistently.